filmov

tv

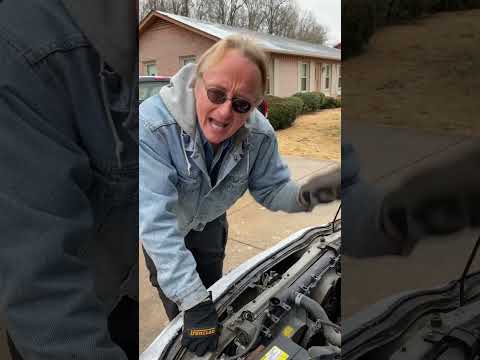

STOP Using Hose Clamps WRONG - LEARN A BETTER WAY

Показать описание

Leaking hoses can cause damage & even wreck an engine. Learn a better way to make LEAK FREE CONNECTIONS with the SMARTEST CLAMPS on the PLANET

This video, description and comments contain affiliate links, which means that if you click on one of the product links, I’ll receive a small commission. This helps support the channel and allows us to continue to make videos like this. Thank you for the support!

Disclaimer:

Due to factors beyond the control of Silver Cymbal, I cannot guarantee against improper use or unauthorized modifications of this information. Silver Cymbal assumes no liability for property damage or injury incurred as a result of any of the information contained in this video. Use this information at your own risk. Silver Cymbal recommends safe practices when working on machines and or with tools seen or implied in this video. Due to factors beyond the control of Silver Cymbal, no information contained in this video shall create any expressed or implied warranty or guarantee of any particular result. Any injury, damage, or loss that may result from improper use of these tools, equipment, or from the information contained in this video is the sole responsibility of the user and not Silver Cymbal.

This video, description and comments contain affiliate links, which means that if you click on one of the product links, I’ll receive a small commission. This helps support the channel and allows us to continue to make videos like this. Thank you for the support!

Disclaimer:

Due to factors beyond the control of Silver Cymbal, I cannot guarantee against improper use or unauthorized modifications of this information. Silver Cymbal assumes no liability for property damage or injury incurred as a result of any of the information contained in this video. Use this information at your own risk. Silver Cymbal recommends safe practices when working on machines and or with tools seen or implied in this video. Due to factors beyond the control of Silver Cymbal, no information contained in this video shall create any expressed or implied warranty or guarantee of any particular result. Any injury, damage, or loss that may result from improper use of these tools, equipment, or from the information contained in this video is the sole responsibility of the user and not Silver Cymbal.

Комментарии