filmov

tv

Easy Vias on Home PCBs

Показать описание

A whole bunch of tips for dealing with vias on home made PCBs.

For more information on how to make home made PCBs, see this video:

For more information on how to make home made PCBs, see this video:

Easy Vias on Home PCBs

DIY PCBs At Home (Single Sided Presensitized)

Connectivity of PCB Layers, vias on a home-made PCB

Making Professional PCB at Home

DIY Double sided PCB with Vias | Best Method

DIY Double Sided PCB

PCB Creation for Beginners - Start to finish tutorial in 10 minutes

Making of PCBs at home, DIY using inexpenive materials

How to Design & PCB Etching- Part 2

How To Make A PCB At Home | Diy PCB Board | How To Make PCB Board

PCB prototyping, PCB making at home - WEGSTR

PCB Plating without Chemicals

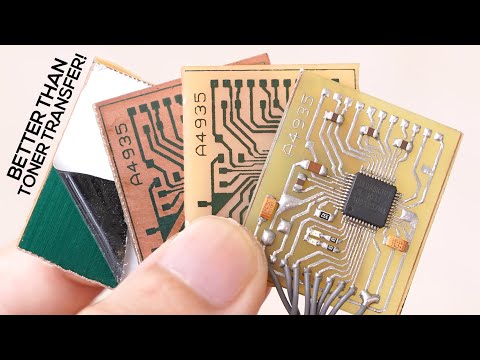

High Quality DIY PCB Boards at Home, Step by Step detailed Instructions (PLUS SMD SOLDERING)

Easy Way to Make your Own Double Sided PCB at Home

#Vias on a home PCB DIY FLAT/FLUSH Thermal Through Hole VIA'S using End Milling Technique

DIY PCB | DIY PCB Etching | DIY PCB at Home | DIY PCB Making | Current Booster Circuit

Vias on a home-made PCB

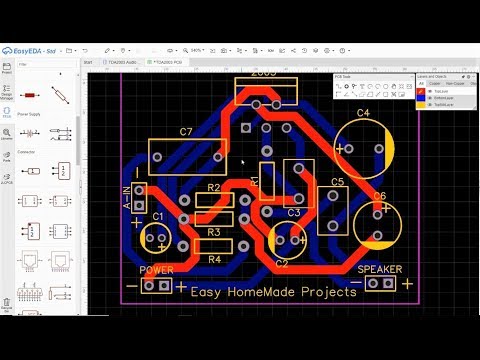

How to Design a PCB easily with EasyEDA & JLCPCB - Complete Tutorial

Connecting the #pxlDigit PCB via JST connectors easily

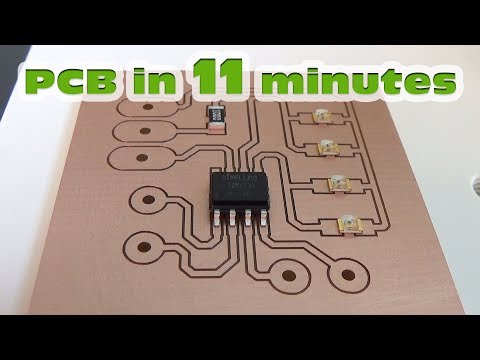

PCB making, PCB prototyping quickly and easy - STEP by STEP

How To Make Circuit Boards (PCBs) at Home Easily

Learn PCB Designing Just in 15 Minutes! EasyEDA + JLCPCB Complete Tutorial 2023

Soldering 101: How to solder to VIAs on PCBs

Homemade PCBs with Fiber Laser - 0.1mm Clearance

Комментарии

0:06:41

0:06:41

0:10:11

0:10:11

0:01:26

0:01:26

0:12:04

0:12:04

0:28:23

0:28:23

0:08:59

0:08:59

0:10:40

0:10:40

0:04:38

0:04:38

0:04:09

0:04:09

0:03:29

0:03:29

0:08:11

0:08:11

0:00:33

0:00:33

0:45:41

0:45:41

0:18:48

0:18:48

0:04:39

0:04:39

0:02:54

0:02:54

0:04:09

0:04:09

0:19:46

0:19:46

0:00:31

0:00:31

0:10:16

0:10:16

0:08:12

0:08:12

0:17:13

0:17:13

0:18:16

0:18:16

0:44:57

0:44:57