filmov

tv

What Size Wire Do I Use To Wire My Solar Components? Does Wire Size Matter?

Показать описание

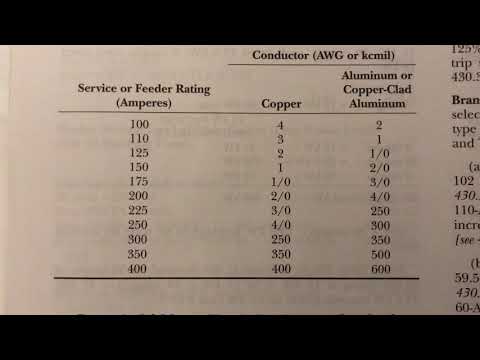

This is a question that in the beginning was confusing but with a little research it all makes sense now.... Most common wires for AC and DC applications are rated at 600v which means they can handle up to 600v. You can use them in 12v systems and 240v systems but the size matters. The other way wires are rated at is in gauges better seen as AWG . This AWG is the most important number you will need to know becus it will tell you how many amps that wire will hold. for example if you have a 14 awg wire regardless of the volts you are using you can only run up to 15amps in that wire.

Bigger is better it does reduce loss but if you go to big your connections become difficult to work becus of the size of components.

Here are some links you might want to check out (amazon affiliate):

Shop Arizona Hot Homestead Merchandise. Shirts, Hats, Mugs, Magnets, Hoodies, etc.

Subscribe to my Youtube channel by clicking the link

Arizona Hot Homestead Website.

Links to all of my social media (Facebook, Tiktok, Instagram, X), website, amazon store and more.

Donate PayPal

** This video may contain affiliate links, which means that if you click on one of the product links, I'll receive a small commission.

All music if from Photoshop elements 13 and or youtube free music library.

Bigger is better it does reduce loss but if you go to big your connections become difficult to work becus of the size of components.

Here are some links you might want to check out (amazon affiliate):

Shop Arizona Hot Homestead Merchandise. Shirts, Hats, Mugs, Magnets, Hoodies, etc.

Subscribe to my Youtube channel by clicking the link

Arizona Hot Homestead Website.

Links to all of my social media (Facebook, Tiktok, Instagram, X), website, amazon store and more.

Donate PayPal

** This video may contain affiliate links, which means that if you click on one of the product links, I'll receive a small commission.

All music if from Photoshop elements 13 and or youtube free music library.

Комментарии

0:10:10

0:10:10

0:04:52

0:04:52

0:07:26

0:07:26

0:03:29

0:03:29

0:10:28

0:10:28

0:04:33

0:04:33

0:11:47

0:11:47

0:04:00

0:04:00

0:14:21

0:14:21

0:02:07

0:02:07

0:11:40

0:11:40

0:02:27

0:02:27

0:26:04

0:26:04

0:07:15

0:07:15

0:05:59

0:05:59

0:08:42

0:08:42

0:14:48

0:14:48

0:02:20

0:02:20

0:05:52

0:05:52

0:02:00

0:02:00

0:05:50

0:05:50

0:02:42

0:02:42

0:02:36

0:02:36

0:10:35

0:10:35