filmov

tv

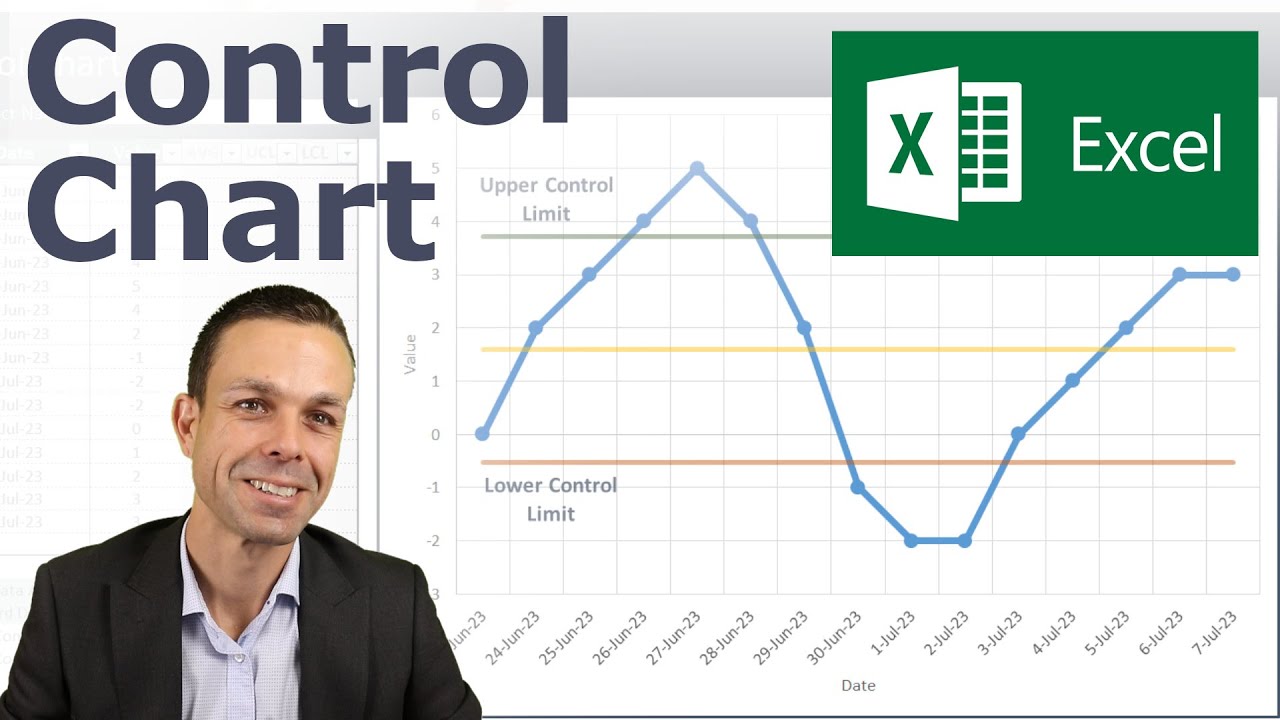

Making a Control Chart in Excel (with dynamic control lines!)

Показать описание

👍 Ready made and ready to use.

Follow along and learn how to make a Control Chart in Excel, with upper and lower control limits and dynamically moving labels.

See how to make a straight horizontal line on a line chart (for the upper and lower control limits).

Timestamps:

00:00 Intro and Control Chart overview

01:01 Starting with blank template - colours

01:27 Making the data table

02:59 Creating the Upper and Lower control limit data

04:46 Creating the control chart basics

06:48 Adding the UCL and LCL lines on the control chart

08:45 Dynamic named labels for the UCL and LCL lines

10:25 Outro and sheet overview

#Excel #SixSigma #ProjectManagement

Follow along and learn how to make a Control Chart in Excel, with upper and lower control limits and dynamically moving labels.

See how to make a straight horizontal line on a line chart (for the upper and lower control limits).

Timestamps:

00:00 Intro and Control Chart overview

01:01 Starting with blank template - colours

01:27 Making the data table

02:59 Creating the Upper and Lower control limit data

04:46 Creating the control chart basics

06:48 Adding the UCL and LCL lines on the control chart

08:45 Dynamic named labels for the UCL and LCL lines

10:25 Outro and sheet overview

#Excel #SixSigma #ProjectManagement

Making a Control Chart in Excel (with dynamic control lines!)

Create a Basic Control Chart | HOW TO CREATE CONTROL CHARTS IN EXCEL | Shewhart Control Chart

How to Construct a Control Chart in Excel

How to make Run Chart and Control Chart

Control Charts simply explained - Statistical process control - Xbar-R Chart, I-MR Chart,...

Create a Basic Control Chart

How to Create a Control Chart

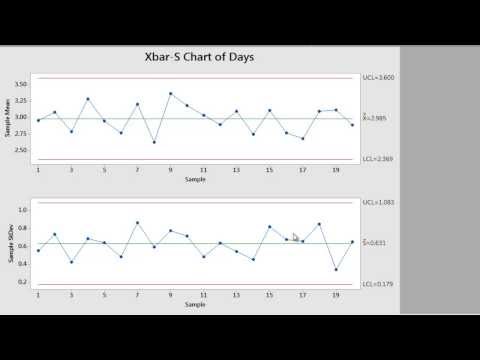

How to Create Control Charts in Minitab Statistical Software

Core Tools syllabus

How to Create Control Charts using Minitab 17

p-Chart in Excel | Control Chart | LCL & UCL

CONTROL CHART BASICS and the X-BAR AND R CHART +++++ EXAMPLE

Create a Control Chart

Create the Perfect Control Chart for SPC in Excel - MiniTab not Required

XBar-R Control Charts

How do SPC control charts work?

Create a Basic Control Chart | HOW TO CREATE CONTROL CHARTS IN EXCEL | Shewhart Control Chart

How to Create a Control Chart (Process Behavior Chart)

What is a Control Chart?? #SPC #LeanSixSigma #OpEx #SixSigma #Lean #ASQGreenBelt #CSSGB

Power BI Control Chart: Create Automatically, Improve Processes Continuously 📈

HOW TO CREATE CONTROL CHARTS ON EXCEL | Step by Step guide by Lean6Sigma

Easily Learn how to create Control Chart in Excel Sheet

Automated Control Chart in Excel (with built-in Data Simulation)

How To Create a Control Chart In Excel

Комментарии

0:11:03

0:11:03

0:15:14

0:15:14

0:01:00

0:01:00

0:06:47

0:06:47

0:11:04

0:11:04

0:09:55

0:09:55

0:07:49

0:07:49

0:04:25

0:04:25

0:07:34

0:07:34

0:05:08

0:05:08

0:03:34

0:03:34

0:12:16

0:12:16

0:04:43

0:04:43

0:28:08

0:28:08

0:05:50

0:05:50

0:08:49

0:08:49

0:13:10

0:13:10

0:16:16

0:16:16

0:00:33

0:00:33

0:09:21

0:09:21

0:09:40

0:09:40

0:05:18

0:05:18

0:41:49

0:41:49

0:17:30

0:17:30