filmov

tv

Oxyacetylene Welding For Total Beginners (OA Welding)

Показать описание

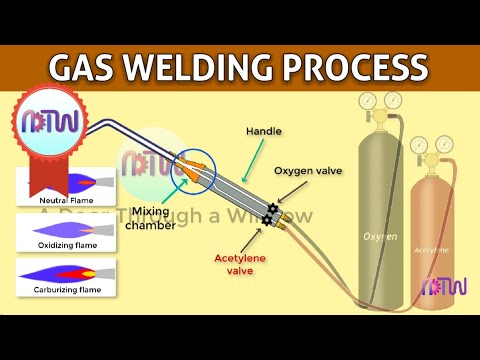

Learn about one of the oldest forms of welding, oxyfuel welding with oxygen & acetylene.

Check Out The Great Gear From Our Trusted Partners

Connect with us!

Subscribe to our Podcast

Ways to Work with Us

Question - Do you think that welding students should have to learn to oxyfuel weld first?

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK.

EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

Time Codes

00:00 Introduction

00:39 Oxyfuel Welding Equipment Overview

01:32 Getting Set Up For Oxyfuel Welding

02:32 Setting Your Gas Pressures

03:18 Lighting Your Oxyfuel Torch

04:40 Proper PPE For Oxyfuel Welding

05:35 Different Types Of Oxyfuel Flames

07:00 Making A Puddle With Oxyfuel Welding

07:31 Moving A Puddle With Oxyfuel Welding

07:57 Adding Filler To Your Oxyfuel Welding Puddle

09:17 Welding With A Dirty Torch Tip

09:45 Welding Two Pieces Of Metal Together (Butt Joint)

#oxyfuelwelding #torchwelding #oxygenacetylene #welding #welddotcom

Check Out The Great Gear From Our Trusted Partners

Connect with us!

Subscribe to our Podcast

Ways to Work with Us

Question - Do you think that welding students should have to learn to oxyfuel weld first?

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK.

EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

Time Codes

00:00 Introduction

00:39 Oxyfuel Welding Equipment Overview

01:32 Getting Set Up For Oxyfuel Welding

02:32 Setting Your Gas Pressures

03:18 Lighting Your Oxyfuel Torch

04:40 Proper PPE For Oxyfuel Welding

05:35 Different Types Of Oxyfuel Flames

07:00 Making A Puddle With Oxyfuel Welding

07:31 Moving A Puddle With Oxyfuel Welding

07:57 Adding Filler To Your Oxyfuel Welding Puddle

09:17 Welding With A Dirty Torch Tip

09:45 Welding Two Pieces Of Metal Together (Butt Joint)

#oxyfuelwelding #torchwelding #oxygenacetylene #welding #welddotcom

Комментарии

0:12:06

0:12:06

0:11:54

0:11:54

0:06:16

0:06:16

0:01:00

0:01:00

0:00:57

0:00:57

0:32:58

0:32:58

0:05:55

0:05:55

0:26:29

0:26:29

0:24:32

0:24:32

0:02:55

0:02:55

0:04:15

0:04:15

0:00:16

0:00:16

0:06:16

0:06:16

0:18:52

0:18:52

0:45:05

0:45:05

0:05:43

0:05:43

0:00:30

0:00:30

0:01:29

0:01:29

0:05:14

0:05:14

0:00:13

0:00:13

0:00:27

0:00:27

0:00:15

0:00:15

0:00:18

0:00:18

0:00:25

0:00:25