filmov

tv

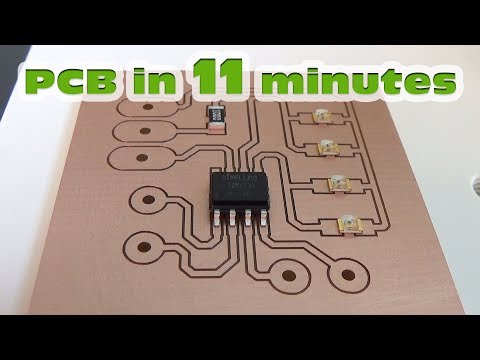

PCB prototyping, PCB making at home - WEGSTR

Показать описание

Experience the fascinating world of PCB manufacturing with this step-by-step video guide. Learn the art of making high-quality PCBs using a CNC milling machine, specifically the Wegstr model. From prototyping to final production, we cover every aspect of the process. Explore the precision of milling, the creation of double-layer PCBs, and the application of solder mask. Follow along as we demonstrate how to make PCBs at home, perfect for your Arduino projects. Gain valuable insights into the PCB manufacturing industry and unleash your creativity with professional-grade results. Don't miss this comprehensive tutorial on making PCBs, a must-watch for electronics enthusiasts, hobbyists, and professionals alike.

The Wegstr CNC milling machine is not only suitable for individuals, but also for businesses, institutions, and schools. Its versatility and precision make it a valuable tool for various industries and educational settings. Whether you're a professional engineer, a research institution, or a school teaching electronics and prototyping, the Wegstr machine can meet your PCB manufacturing needs. Its robust construction, advanced features, and user-friendly interface make it a reliable choice for both small-scale production and larger projects. Unlock the potential of PCB manufacturing with the Wegstr CNC milling machine, tailored for individuals, businesses, institutions, and schools alike.

This video is showing some useful tools and procedures designing PCBs.

Thanks for watching. Comments and ratings are of course welcome.

The Wegstr CNC milling machine is not only suitable for individuals, but also for businesses, institutions, and schools. Its versatility and precision make it a valuable tool for various industries and educational settings. Whether you're a professional engineer, a research institution, or a school teaching electronics and prototyping, the Wegstr machine can meet your PCB manufacturing needs. Its robust construction, advanced features, and user-friendly interface make it a reliable choice for both small-scale production and larger projects. Unlock the potential of PCB manufacturing with the Wegstr CNC milling machine, tailored for individuals, businesses, institutions, and schools alike.

This video is showing some useful tools and procedures designing PCBs.

Thanks for watching. Comments and ratings are of course welcome.

Комментарии

0:00:54

0:00:54

0:12:23

0:12:23

0:08:11

0:08:11

0:10:36

0:10:36

0:12:29

0:12:29

0:02:11

0:02:11

0:06:52

0:06:52

0:00:56

0:00:56

1:09:29

1:09:29

0:10:40

0:10:40

0:12:09

0:12:09

0:03:41

0:03:41

0:01:29

0:01:29

0:24:29

0:24:29

0:01:41

0:01:41

0:05:40

0:05:40

0:05:11

0:05:11

0:09:28

0:09:28

0:08:34

0:08:34

0:05:35

0:05:35

0:10:16

0:10:16

0:06:19

0:06:19

0:13:10

0:13:10

0:09:49

0:09:49