filmov

tv

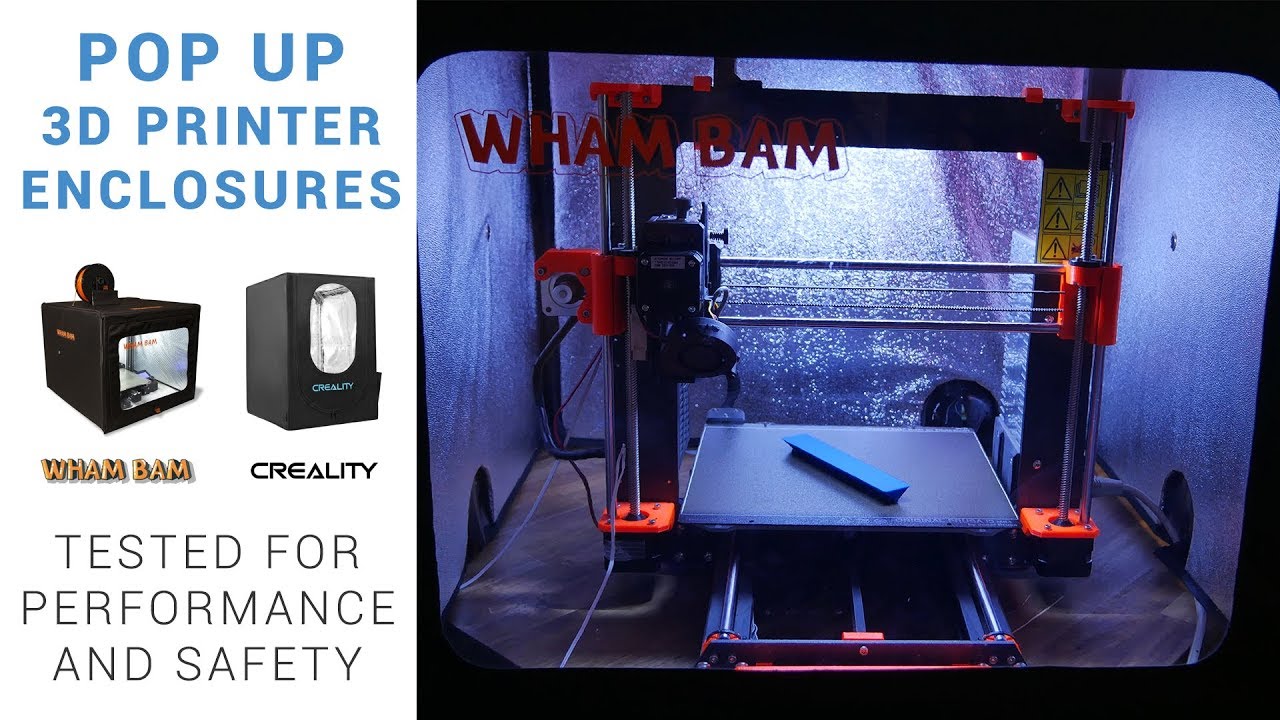

Pop up 3D printer enclosures tested - Creality vs Wham Bam

Показать описание

I had the chance to see how effective two pop up enclosures would be when printing a difficult ABS print. In this video, I conduct back to back print tests and monitor temperatures in the enclosure as well as in each printer's electronic housing.

My results showed the enclosures did indeed raise the temperatures inside but with my Zortrax filament, this gave no reduction of warping. Your results may vary, please leave them in the comments.

Both printers suffered from some mishaps due to raised temperatures. Running the mainboard, stepper motors and especially the power supply at higher temperatures will shorten their lifespan and might lead to premature failure. If using any type of heated enclosure, I strongly advise moving these components outside of the heated area or adding ducted cool air.

If I had to choose between the two, I feel the Wham Bam is a more polished product and easier to deploy and pack away when needed. Both products provided free of charge for this test. All opinions expressed are my own.

My previous videos on adding a lid and heater to my Ender 5:

Get Quality Resins from 3D Printers Online. 5% off storewide for Teaching Tech subscribers [Code: tech5]

Take a look around and if you like what you see, please subscribe.

My results showed the enclosures did indeed raise the temperatures inside but with my Zortrax filament, this gave no reduction of warping. Your results may vary, please leave them in the comments.

Both printers suffered from some mishaps due to raised temperatures. Running the mainboard, stepper motors and especially the power supply at higher temperatures will shorten their lifespan and might lead to premature failure. If using any type of heated enclosure, I strongly advise moving these components outside of the heated area or adding ducted cool air.

If I had to choose between the two, I feel the Wham Bam is a more polished product and easier to deploy and pack away when needed. Both products provided free of charge for this test. All opinions expressed are my own.

My previous videos on adding a lid and heater to my Ender 5:

Get Quality Resins from 3D Printers Online. 5% off storewide for Teaching Tech subscribers [Code: tech5]

Take a look around and if you like what you see, please subscribe.

Комментарии

0:14:09

0:14:09

0:18:07

0:18:07

0:07:20

0:07:20

0:10:15

0:10:15

0:09:03

0:09:03

0:08:12

0:08:12

0:04:31

0:04:31

0:01:01

0:01:01

0:00:11

0:00:11

0:07:18

0:07:18

0:11:48

0:11:48

0:08:01

0:08:01

0:08:55

0:08:55

0:05:23

0:05:23

0:09:56

0:09:56

0:11:43

0:11:43

0:06:41

0:06:41

0:00:41

0:00:41

0:00:25

0:00:25

0:11:20

0:11:20

0:09:47

0:09:47

0:06:58

0:06:58

0:08:26

0:08:26

0:21:42

0:21:42