filmov

tv

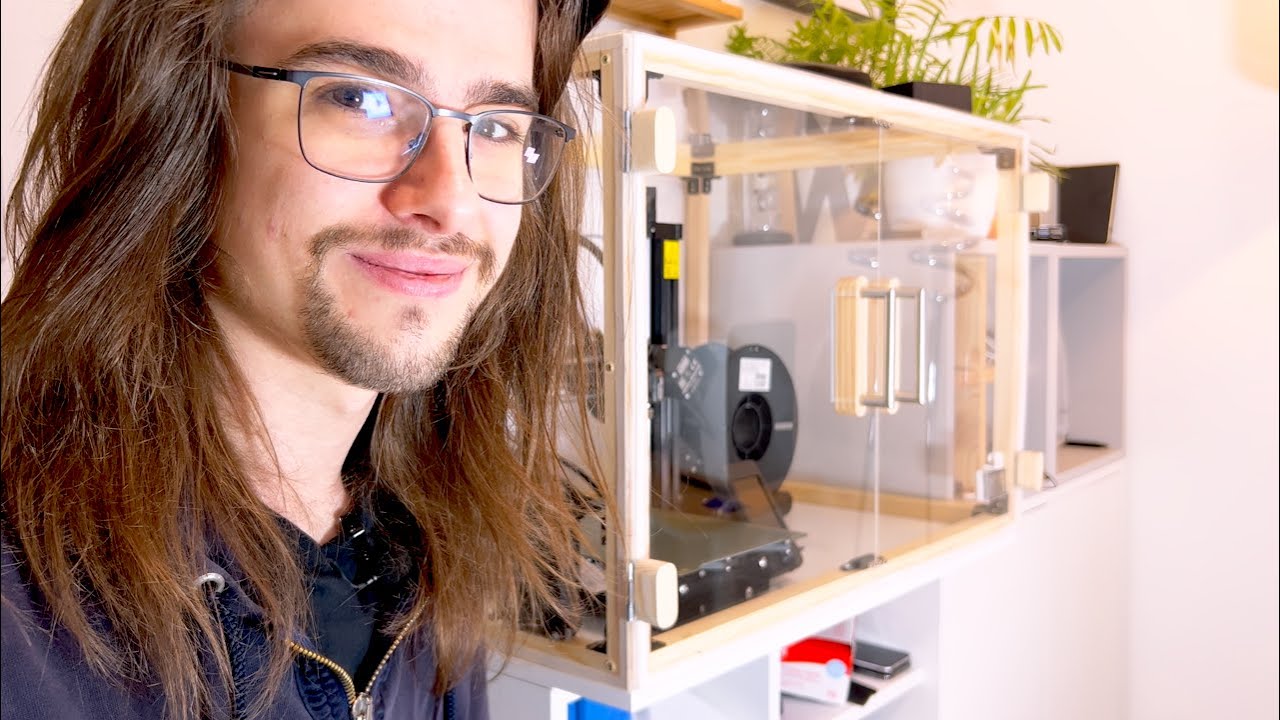

Building a Budget-Friendly 3D Printer Enclosure from Scratch

Показать описание

3D Printer enclosures are too expensive, so I built one from scratch!

My Prusa MINI+ was struggling with ABS print warping on the print bed, even at 100C. The issue? I didn't have an enclosure to keep warmer air around layers towards the top of prints. Looking online I found that off-the-shelf solutions were too expensive for my budget, so I built this one from pine and 2mm acrylic sheets.

🌐 Links

PDF of the design:

STL files for the frame brackets, and magnetic clasps

😎 Social Stuff

🎞️ Chapters

00:00 - Introduction

01:46 - Frame assembly

04:56 - Acrylic panels

06:22 - Door clasps

08:19 - Showcase

10:00 - Future improvements

ℹ️ Attributions

Fabweaver - Warping diagram

🎵 Music

TABAL - Inside Space

nihilore - Garden

Punch Deck - Persistence

Grease - You're The One That I Want

Alex-Productions - Startup

Corbyn Kites - Instant Crush

Home - We're Finally Landing

Keywords: Prusa Mini, 3D Printer, ABS warping, DIY

My Prusa MINI+ was struggling with ABS print warping on the print bed, even at 100C. The issue? I didn't have an enclosure to keep warmer air around layers towards the top of prints. Looking online I found that off-the-shelf solutions were too expensive for my budget, so I built this one from pine and 2mm acrylic sheets.

🌐 Links

PDF of the design:

STL files for the frame brackets, and magnetic clasps

😎 Social Stuff

🎞️ Chapters

00:00 - Introduction

01:46 - Frame assembly

04:56 - Acrylic panels

06:22 - Door clasps

08:19 - Showcase

10:00 - Future improvements

ℹ️ Attributions

Fabweaver - Warping diagram

🎵 Music

TABAL - Inside Space

nihilore - Garden

Punch Deck - Persistence

Grease - You're The One That I Want

Alex-Productions - Startup

Corbyn Kites - Instant Crush

Home - We're Finally Landing

Keywords: Prusa Mini, 3D Printer, ABS warping, DIY

I Bought the 5 Cheapest 3D Printers on Amazon

The 3D Printer I'd buy if I started over

$100 3D Printer - The Ender 3

TOP 3: Best Budget 3D Printers 2024

A Hassle-Free 3D Printer

Honest 3D printer buyer’s guide: Find the best machine for you!

Fast Affordable 3D Printers - Elegoo Neptune 4 / 4 Pro

Best 3D Printers of 2023! A Guide for Beginners, Budgets, & More!

5 Best 3D Printers 2025 | Top Picks & Reviews

Testing Cheap vs. Expensive 3D Printer!

HOW to BUY a 3D Printer in 2024! 13 Budget Friendly Options!

Budget & Beginner Friendly 3D Printer Only $200 - Creality Ender 3 V3 SE

How bad is a $69 3D Printer?

✅Top 5 Best Budget 3D Printers of 2024

HUGE FAST & AFFORDABLE? - $470 Elegoo Neptune 4 Max 3D Printer

Which 3D Printer Should You Get? A COMPLETE Beginner's Guide

Which 3D Printer Should YOU Buy?

Best CHEAP Resin 3D Printer?! Voxelab Polaris Review

The Best 3D Printers for You | Micro Center

Best 3D Printers in 2024- easy to use, budget friendly

Best Budget 3D Printer In 2024 (Top 5 Picks For Beginners & Experts)

The Cheapest BIG 3D Printer Out There - Is It Any Good? (Longer LK5 Pro Review)

✅ Best Beginner 3D Printers of 2024

TOP 3: Best Budget 3D Printer 2023

Комментарии

0:12:32

0:12:32

0:12:56

0:12:56

0:00:10

0:00:10

0:06:04

0:06:04

0:00:22

0:00:22

0:14:46

0:14:46

0:10:48

0:10:48

0:24:16

0:24:16

0:09:48

0:09:48

0:00:25

0:00:25

0:27:05

0:27:05

0:03:33

0:03:33

0:04:20

0:04:20

0:08:46

0:08:46

0:17:19

0:17:19

0:17:02

0:17:02

0:21:51

0:21:51

0:08:55

0:08:55

0:09:39

0:09:39

0:06:04

0:06:04

0:06:12

0:06:12

0:21:53

0:21:53

0:11:01

0:11:01

0:07:35

0:07:35