filmov

tv

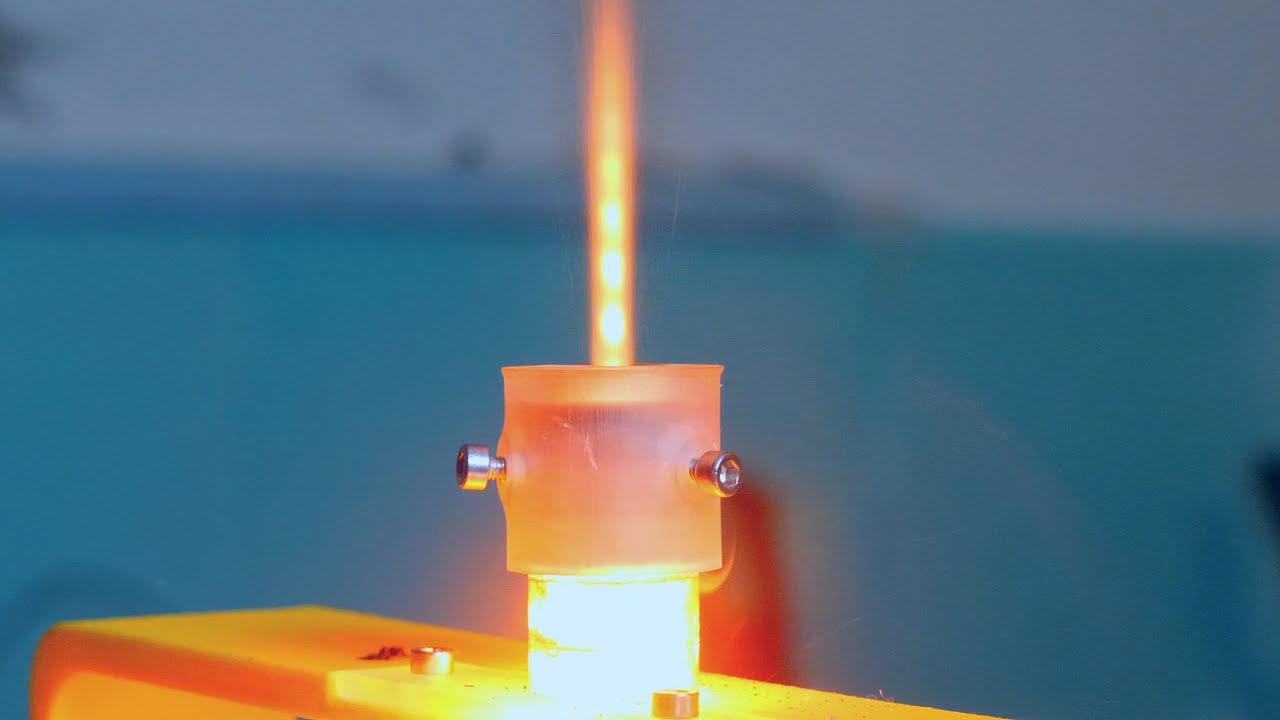

I built a PULSED ROCKET ENGINE

Показать описание

Printers I used

#rocket #engine #3dprinted

I built a PULSED ROCKET ENGINE

I built a Pulsed Rocket Engine #shorts

I Built The First LAMINAR FLOW ROCKET ENGINE

fire death machine - i made a rocket

can a Rocket Engine powered by Nuclear ?? #elonmusk

Can I Make an Aerospike Rocket at Home? #shorts

GAME OVER - A.I. Designs CRAZY New ROCKET Engine

I turned my Fan into a Jet Engine (3D Printed EDF Afterburner)

I built an Electric Jet Engine from scratch

Carbon Fiber Jet Engine

Crazy Nuclear Rocket Engine #4 - Pulsed Solid Core

Project Orion Nuclear Pulse Rocket

I 3D PRINTED a METAL ROCKET at HOME #shorts

GLASS ROCKET ENGINE

Project Orion Nuclear Pulse Rocket

Making Sugar Rocket Fuel

sugar rocket gone wrong #experiment #rocketry #sugarrocket

I 3D printed a CO2 Rocket

How NASA Reinvented the Rocket Engine

4 Stage Nuclear Rocket!! 🚀

That Time NASA Tried to Make a Nuclear-Powered Rocket

Home made Rocket engine (DIY MINI) 🚀🚀

TurboCharged PulseJet Engine (3D Printed)

Game Changer: New Pulsed Plasma Rocket Could Get Us to Mars in 2 Months

Комментарии

0:11:33

0:11:33

0:01:00

0:01:00

0:15:51

0:15:51

0:10:39

0:10:39

0:00:48

0:00:48

0:00:57

0:00:57

0:05:26

0:05:26

0:16:00

0:16:00

0:15:13

0:15:13

0:13:32

0:13:32

0:05:59

0:05:59

0:00:55

0:00:55

0:01:00

0:01:00

0:16:24

0:16:24

0:10:52

0:10:52

0:00:28

0:00:28

0:00:20

0:00:20

0:09:43

0:09:43

0:18:11

0:18:11

0:00:22

0:00:22

0:07:25

0:07:25

0:00:48

0:00:48

0:20:22

0:20:22

0:08:20

0:08:20