filmov

tv

NASA's Perseverance Rover Bringing 3D Printed Metal Parts to Mars

Показать описание

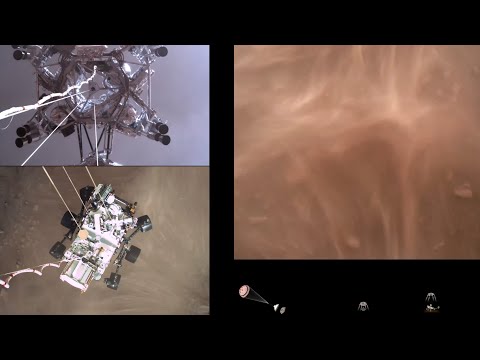

NASA is exploring the 3D printing technique, known as additive manufacturing when used by specialized engineers, to build rocket engines as well as potential outposts on the Moon and Mars. It's one of several ways parts are 3D printed at NASA's Jet Propulsion Laboratory. Curiosity, Perseverance's predecessor, was the first mission to take 3D printing to the Red Planet. It landed in 2012 with a 3D-printed ceramic part inside the rover's ovenlike Sample Analysis at Mars instrument. NASA has since continued to test 3D printing for use in spacecraft to make sure the reliability of the parts is well understood. Nearer in the future is a different milestone. NASA's Perseverance rover, which lands on the Red Planet on February 18, 2021, carries 11 metal parts made with 3D printing.

The outer shell of PIXL, one of the instruments aboard NASA's Perseverance Mars rover, includes several parts that were made of 3D-printed titanium. Of the 11 printed parts going to Mars, five are in Perseverance's PIXL instrument. Short for the Planetary Instrument for X-ray Lithochemistry, the lunchbox-size device will help the rover seek out signs of fossilized microbial life by shooting X-ray beams at rock surfaces to analyze them.

PIXL shares space with other tools in the 40-kilogram rotating turret at the end of the rover's 7-foot-long. To make the instrument as light as possible, the JPL team designed PIXL's two-piece titanium shell, a mounting frame, and two support struts that secure the shell to the end of the arm to be hollow and extremely thin. In fact, the parts, which were 3D printed by a vendor called Carpenter Additive, have three or four times less mass than if they'd been produced conventionally.

Perseverance's six other 3D-printed parts can be found in an instrument called the Mars Oxygen In-Situ Resource Utilization Experiment, or MOXIE. This device will test technology that, in the future, could produce industrial quantities of oxygen to create rocket propellant on Mars, helping astronauts launch back to Earth. To create oxygen MOXIE heats Martian air up to nearly 800 degrees Celsius. Within the device are six heat exchangers, palm-size nickel-alloy plates that protect key parts of the instrument from the effects of high temperatures. While a conventionally machined heat exchanger would need to be made out of two parts and welded together, MOXIE's were each 3D-printed as a single piece at nearby Caltech, which manages JPL for NASA.

A key objective of Perseverance's mission on Mars is astrobiology, including the search for signs of ancient microbial life. The rover will characterize the planet's geology and past climate, pave the way for human exploration of the Red Planet, and be the first mission to collect and cache Martian rock and regolithm broken rock and dust. Subsequent missions, currently under consideration by NASA in cooperation with the European Space Agency, would send spacecraft to Mars to collect these cached samples from the surface and return them to Earth for in-depth analysis.

The Mars 2020 mission is part of a larger program that includes missions to the Moon as a way to prepare for human exploration of the Red Planet. Charged with returning astronauts to the Moon by 2024, NASA will establish a sustained human presence on and around the Moon by 2028 through NASA's Artemis lunar exploration plans.

#SteelGuruBusinessNews #OnlineNews #BusinessNews #AerospaceNews #3DPrintingNews #NASA #PerseveranceRover #3DPrintedParts

The outer shell of PIXL, one of the instruments aboard NASA's Perseverance Mars rover, includes several parts that were made of 3D-printed titanium. Of the 11 printed parts going to Mars, five are in Perseverance's PIXL instrument. Short for the Planetary Instrument for X-ray Lithochemistry, the lunchbox-size device will help the rover seek out signs of fossilized microbial life by shooting X-ray beams at rock surfaces to analyze them.

PIXL shares space with other tools in the 40-kilogram rotating turret at the end of the rover's 7-foot-long. To make the instrument as light as possible, the JPL team designed PIXL's two-piece titanium shell, a mounting frame, and two support struts that secure the shell to the end of the arm to be hollow and extremely thin. In fact, the parts, which were 3D printed by a vendor called Carpenter Additive, have three or four times less mass than if they'd been produced conventionally.

Perseverance's six other 3D-printed parts can be found in an instrument called the Mars Oxygen In-Situ Resource Utilization Experiment, or MOXIE. This device will test technology that, in the future, could produce industrial quantities of oxygen to create rocket propellant on Mars, helping astronauts launch back to Earth. To create oxygen MOXIE heats Martian air up to nearly 800 degrees Celsius. Within the device are six heat exchangers, palm-size nickel-alloy plates that protect key parts of the instrument from the effects of high temperatures. While a conventionally machined heat exchanger would need to be made out of two parts and welded together, MOXIE's were each 3D-printed as a single piece at nearby Caltech, which manages JPL for NASA.

A key objective of Perseverance's mission on Mars is astrobiology, including the search for signs of ancient microbial life. The rover will characterize the planet's geology and past climate, pave the way for human exploration of the Red Planet, and be the first mission to collect and cache Martian rock and regolithm broken rock and dust. Subsequent missions, currently under consideration by NASA in cooperation with the European Space Agency, would send spacecraft to Mars to collect these cached samples from the surface and return them to Earth for in-depth analysis.

The Mars 2020 mission is part of a larger program that includes missions to the Moon as a way to prepare for human exploration of the Red Planet. Charged with returning astronauts to the Moon by 2024, NASA will establish a sustained human presence on and around the Moon by 2028 through NASA's Artemis lunar exploration plans.

#SteelGuruBusinessNews #OnlineNews #BusinessNews #AerospaceNews #3DPrintingNews #NASA #PerseveranceRover #3DPrintedParts

0:00:51

0:00:51

0:01:47

0:01:47

0:03:42

0:03:42

0:03:11

0:03:11

0:06:31

0:06:31

0:05:08

0:05:08

0:17:47

0:17:47

0:00:34

0:00:34

0:02:59

0:02:59

0:02:21

0:02:21

0:00:46

0:00:46

0:03:09

0:03:09

0:01:01

0:01:01

0:04:27

0:04:27

0:00:41

0:00:41

0:00:43

0:00:43

0:03:26

0:03:26

0:00:25

0:00:25

0:00:45

0:00:45

0:00:19

0:00:19

0:19:42

0:19:42

0:07:41

0:07:41

0:16:14

0:16:14

0:00:58

0:00:58