filmov

tv

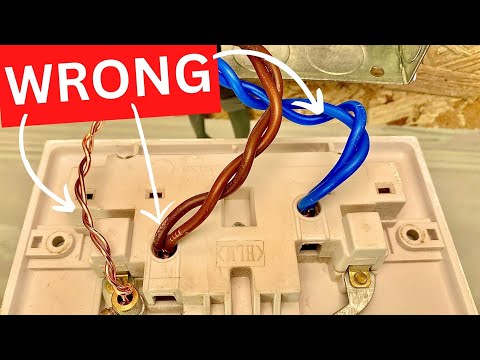

BIGGEST DIY Mistakes Joining Cables

Показать описание

Common mistakes joining cables, and how to address these issues.

Amazon Affliate links for great electrical tools:

Amazon Affliate links for great electrical tools:

BIGGEST DIY Mistakes Joining Cables

5 Biggest DIY Mistakes Wiring a Socket

BIGGEST DIY Mistakes Adding a New Socket

Biggest Mistakes DIYers Make When Connecting Wires Together | Part 2

5 CLEVER Electrical Tricks Everyone Should Know

BIGGEST DIY Mistakes with Downlights

10 Mistakes EVERYONE Makes When Doing DIY Electrics!💥

How to Extend Short Cables: Simple DIY Fix

Most Common DIYer Electrical Mistake - Don't Let This Be You!

Avoid These 5 DIY Electrical Mistakes

BEWARE Of These 3 Common Wiring Mistakes On Outlets & Switches

How to Fix Damaged Cables The Easy Way | Electrical DIY You Need To See!

#1 DIY Electric Mistake - Can you use Romex Wire in Conduit?

Never Solder Again - How to Connect Wires the EASY Way

6 MISTAKES DIYers Make When Wiring Outlets

What Wire Connector is the Best? Settling a Debate! Wire Nut VS Wago

Best Wire Connector For DIY Electrical Projects

Metal Vs Plastic Electrical Boxes | Avoid This Common DIY Mistake

2 Most Common Issues DIYers Make With Metal Electrical Boxes

How to Extend Short Wires. Easy Diy Fix

How To Run Electrical Wires Through Studs

30 second curbless shower #shorts #shortsvideo #diy #tile

How To Solder Copper Pipe Like a Pro (Tips & Tricks) | GOT2LEARN

Wiring an Outlet with Multiple Sets of Wires

Комментарии

0:08:52

0:08:52

0:06:02

0:06:02

0:10:17

0:10:17

0:12:19

0:12:19

0:11:06

0:11:06

0:07:02

0:07:02

0:11:56

0:11:56

0:04:53

0:04:53

0:10:41

0:10:41

0:08:28

0:08:28

0:05:12

0:05:12

0:10:26

0:10:26

0:03:44

0:03:44

0:04:25

0:04:25

0:11:28

0:11:28

0:11:09

0:11:09

0:06:43

0:06:43

0:13:21

0:13:21

0:10:33

0:10:33

0:06:43

0:06:43

0:07:11

0:07:11

0:00:34

0:00:34

0:10:46

0:10:46

0:09:30

0:09:30