filmov

tv

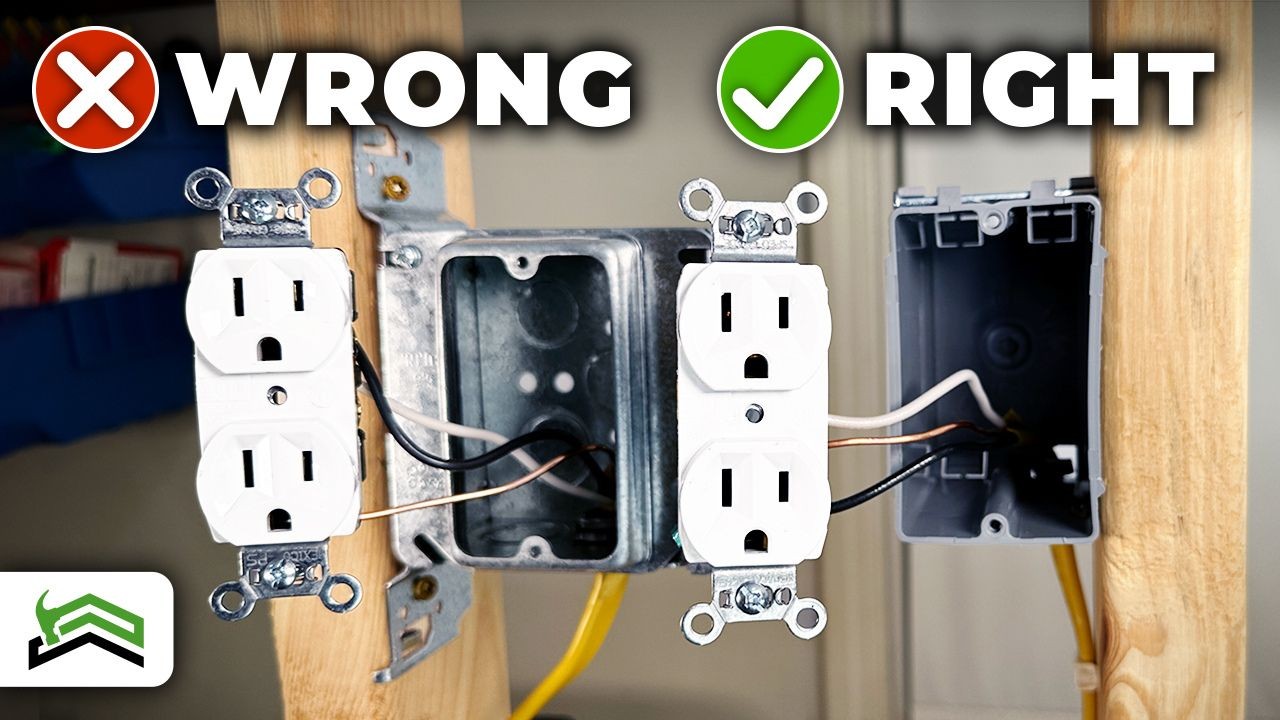

Metal Vs Plastic Electrical Boxes | Avoid This Common DIY Mistake

Показать описание

Do you feel comfortable using metal electrical boxes on your DIY electrical projects around the house? If not, you are like the majority of my audience who indicated they prefer to use plastic boxes. There are a lot of advantages to metal boxes but you do need to have some knowledge to ensure you aren't making common DIY mistakes.

Free Home Maintenance Checklist:

DISCLAIMER: This video and description contain affiliate links, which means that if you click on one of the product links, I’ll receive a small commission.

Steel Electrical Boxes Are Better Than Plastic! (With How-To Details)

Metal Vs Plastic Electrical Boxes | Avoid This Common DIY Mistake

How to Choose an Electrical Box | Ask This Old House

Is it better to use metal or plastic electrical boxes?

Different Types of Electrical Boxes

Why We Bond Metal Boxes? Do Plastic Boxes Need Bonding?

5 Mistakes DIYers make using metal electrical boxes

The WAGO Junction Box Debate: Metal or Plastic?

What Wire Connectors Should You Use | Romex Into Metal Box

5 MAJOR Violations DIYers Are Making When Installing Metal Electrical Boxes! MOST Are Guilty Of #3!

2 Most Common Issues DIYers Make With Metal Electrical Boxes

Romex Connectors Metal Versus Plastic Which Is Better

The BIGGEST Mistakes DIYers Don't Know They Are Making When Installing Metal Electrical Boxes

Stainless Steel vs. Plastic Electrical Boxes: Which Is More Cost-Effective?

Plastic Pattresses and Boxes for UK Electrical Accessories

The Best Metal Remodel Box On The Market

What's the Difference Between Old and New Electrical Outlet Box?

Which Splicing Device is Best? Push Ins Vs. Wago Vs. Wirenuts

Metal vs Plastic Dust Boxes

Old Work Electrical Boxes, Retrofit Boxes, or Remodel Boxes

5 Mistakes Everyone Makes with Metal Electric Boxes

Is This The Best Wago Junction Box?

electrical enclosure box waterproof-Weatherproof Electrical Enclosures

Flexible conduit and weatherproof boxes.

Комментарии

0:06:22

0:06:22

0:13:21

0:13:21

0:04:39

0:04:39

0:00:51

0:00:51

0:20:34

0:20:34

0:16:01

0:16:01

0:07:20

0:07:20

0:03:27

0:03:27

0:10:14

0:10:14

0:08:05

0:08:05

0:10:33

0:10:33

0:06:13

0:06:13

0:09:37

0:09:37

0:05:37

0:05:37

0:18:56

0:18:56

0:12:42

0:12:42

0:01:11

0:01:11

0:13:06

0:13:06

0:05:26

0:05:26

0:10:55

0:10:55

0:06:30

0:06:30

0:01:00

0:01:00

0:00:18

0:00:18

0:00:19

0:00:19