filmov

tv

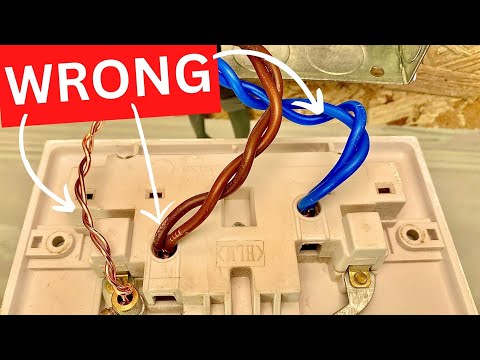

Most Common DIYer Electrical Mistake - Don't Let This Be You!

Показать описание

I have seen this type of failure in about half of the homes we have renovated over the past 2 years. This is an extremely common mistake and often one you will not know about until you start to have failures at your light fixtures or smart home light switches. I will show you 2 solutions for this issue and better prepare you for future home improvement projects.

Wago 221 Lever Nuts

Chapters

0:00 Demonstration of Most Common Mistake

1:04 Proper Wire Nut Installation (Stranded and Solid Wire)

5:13 Our Favorite Tools For DIYers

5:55 My Prefered Wire Connector For DIYers

8:37 Example Of The Holding Strength of Wago 221 for Stranded Wire

9:58 Recap

DISCLAIMER: This video and description contain affiliate links, which means that if you click on one of the product links, I’ll receive a small commission.

Wago 221 Lever Nuts

Chapters

0:00 Demonstration of Most Common Mistake

1:04 Proper Wire Nut Installation (Stranded and Solid Wire)

5:13 Our Favorite Tools For DIYers

5:55 My Prefered Wire Connector For DIYers

8:37 Example Of The Holding Strength of Wago 221 for Stranded Wire

9:58 Recap

DISCLAIMER: This video and description contain affiliate links, which means that if you click on one of the product links, I’ll receive a small commission.

Most Common DIYer Electrical Mistake - Don't Let This Be You!

Most Common DIYer Electrical Mistake When Cutting Cable Sheathing - 5 Tips To Do It Right! HOW TO

BIGGEST Mistakes DIYers Make When Connecting Wires Together | How To

The BIGGEST Mistakes DIYers Don't Know They Are Making When Wiring Receptacles | How To

Avoid These 5 DIY Electrical Mistakes

6 MISTAKES DIYers Make When Wiring Outlets

5 CLEVER Electrical Tricks Everyone Should Know

DIYer's Most Common Electrical Mistake: & How to Prevent It

WORST Electric Connection Made Easy STRANDED & SOLID Wire

Wire Stripping: Almost Everyone Makes This Mistake

5 Biggest DIY Mistakes Wiring a Socket

2 Most Common Issues DIYers Make With Metal Electrical Boxes

Mistakes DIYers Make When Connecting Wires Together A How To With Pro Tips

3 Mistakes DIYers Make When Mounting a TV

6 Ways to Fix Broken Wires - Beginner Through Pro

Biggest Mistakes DIYers Make When Connecting Wires Together | Part 2

Don't make this electrical mistake #Shorts

Most DIYers Overlook this Pex Trick

Most common electrical mistake to avoid #fyp #shorts #electrical mistakes

9 out of 10 DIYers Don't Know All (5 Wire Stripper Features)

BIGGEST DIY Mistakes Adding a New Socket

BIGGEST DIY Mistakes with Downlights

I'm An Electrician. Here Are 10 Things Wrong With My Home's Wiring.

3 Mistakes DIYers Make When Wiring Light Switches

Комментарии

0:10:41

0:10:41

0:10:48

0:10:48

0:13:07

0:13:07

0:12:00

0:12:00

0:08:28

0:08:28

0:11:28

0:11:28

0:11:06

0:11:06

0:03:47

0:03:47

0:04:24

0:04:24

0:09:25

0:09:25

0:06:02

0:06:02

0:10:33

0:10:33

0:08:09

0:08:09

0:14:02

0:14:02

0:13:27

0:13:27

0:12:19

0:12:19

0:00:58

0:00:58

0:01:07

0:01:07

0:01:00

0:01:00

0:05:32

0:05:32

0:10:17

0:10:17

0:07:02

0:07:02

0:05:11

0:05:11

0:09:30

0:09:30