filmov

tv

How to build a Mini Metal Brake

Показать описание

The mini metal brake/bending machine is an easy-to-build open project that requires no welding. An angle grinder, drill and taps are all you need to build it! The miniature size makes it easy to store in the workshop and is just perfect for my projects. If you need a bigger brake, use my plans and scale them up :)

Instagram: nikodembartnik

How To Build A Mini Ramp with Billy Rohan

How to Make Awesome Mini House from Concrete

DIY - How To Build Mini Swimming Pool For Pet From Magnetic Balls (Satisfying) | Magnet World Series

How to Build a Tiny House Step by Step

Build mini hydropower on a small stream with a powerful unit

Build a Mini Trebuchet | STEM Activity

Building a HIGH Revving 4 Cylinder Mini Engine - 4 Stroke Engine Build

How to build a Mini DIY Greenhouse for THRIVING Transplants

Minecraft 1.21.1+ | 3 Mini Games Build Hacks You Can Create In Minecraft 1.21.1+

🍗MINI reinforced concrete construction for KFC 🍗

How to Build Amazing Mini House | Miniature House Hacks and Crafts | New House Project

BRICKLAYING - How to Build Amazing Mini House

DIY- How to Build Mini Rainbow Water Slide To Circus Playground And Swimming Pool From Magnetic Ball

How to Build a MiNi Lego Candy Machine 2

HOW TO MAKE 🍔 Mc Donald's mini🍔 DRIVE THRU--Cómo hacer un mc donald's

Build a Mini Garage with Mini Bricks - Bricklaying Model

Incredible! Dream Modern Future House - How To Make Wonderful Mini Modern Future House

How to Build a MiNi Lego Candy Machine Pocket Sized

How to Build a Mini RAISED BED Using ONE PALLET, FREE Backyard Gardening!

How To Build A Mini ITX PC (Tiny!)

How To Build A Mini Ramp with Danny Way

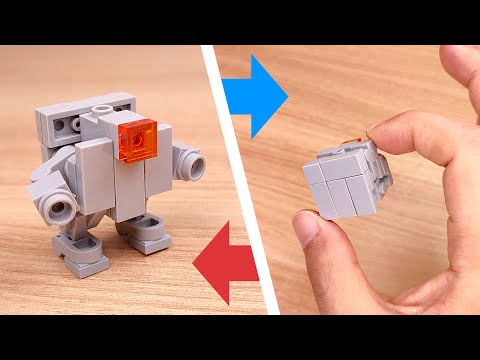

How to build LEGO brick mini cube transformer robot MOC - Cubiko

LEGO MINI VEHICLES Part 1 (Tutorial)

How to Build a Cool & Cheap 3D Printed Mini Drone

Комментарии

0:12:38

0:12:38

0:24:50

0:24:50

0:12:53

0:12:53

0:17:01

0:17:01

0:13:59

0:13:59

0:03:39

0:03:39

0:11:08

0:11:08

0:11:18

0:11:18

0:08:54

0:08:54

0:13:08

0:13:08

0:21:13

0:21:13

0:14:43

0:14:43

0:18:04

0:18:04

0:12:24

0:12:24

0:17:30

0:17:30

0:10:58

0:10:58

0:27:26

0:27:26

0:09:19

0:09:19

0:15:34

0:15:34

0:34:21

0:34:21

0:04:36

0:04:36

0:08:10

0:08:10

0:05:00

0:05:00

0:07:10

0:07:10