filmov

tv

Assembling & Testing a 3D Printed Skateboard. Does It Work. Yes. Sort Of. 3D Printing Cool Stuff!

Показать описание

The skateboard I 3d printed using recycled PET filament. The skateboard would be supported by two smooth rods, a threaded rod would hold together the middle parts, and the trucks would attach and keep it all together. Would it withstand me? Or, how about my 9 year old son?

== Support the Channel via Patreon!

== Donations via Bitcoin / Ethereum / Litecoin are ALWAYS appreciated

Bitcoin: 1L4D7HZ198DHfYyfcKim11cPV1pSvkBzQA

Ethereum: 0x87a3f850c2Bf20D929303200f53aAb8d8d7E2279

Litecoin: LeMZvR4WUCngynZ4D8h2BDUQdqS1GdBwK2

== Cool New T-Shirts!

== Find Me Socially

== Shop at the Affiliate Links Below to Help the Channel!

== Want some 3D Printing Nerd Swag?

Want to send me something for Fan Mail Friday?

attn: 3D Printing Nerd

509 NE 165th st

Shoreline, WA 98155

USA

== Support the Channel via Patreon!

== Donations via Bitcoin / Ethereum / Litecoin are ALWAYS appreciated

Bitcoin: 1L4D7HZ198DHfYyfcKim11cPV1pSvkBzQA

Ethereum: 0x87a3f850c2Bf20D929303200f53aAb8d8d7E2279

Litecoin: LeMZvR4WUCngynZ4D8h2BDUQdqS1GdBwK2

== Cool New T-Shirts!

== Find Me Socially

== Shop at the Affiliate Links Below to Help the Channel!

== Want some 3D Printing Nerd Swag?

Want to send me something for Fan Mail Friday?

attn: 3D Printing Nerd

509 NE 165th st

Shoreline, WA 98155

USA

3D Printing ABS In The Cold! // Assembling and Testing a 3D Printer Enclosure

Assembling & Testing a 3D Printed Skateboard. Does It Work. Yes. Sort Of. 3D Printing Cool Stuff...

3D Printed Bearings - Are These Real Things? (Building and Testing)

How to build gear set for rear differential 3D print

Why your 3d printed stuff doesn't fit together and how to fix it!

How a 3DBenchy can tell where your 3D prints need improvement

First Tests for any 3D Printer ⛵

Complete beginner's guide to 3D printing - Assembly, tour, slicing, levelling and first prints

Quick 3D Printed HO Building Shell

10 Secret 3D Printing Tricks Only Experts Know...

5 must-know 3D printing tips & tricks. (stronger and better looking prints)

Beginners Guide To 3D Printers In 2023

Top 10 3D Printable Tools Every Maker Should, Like, Make

How Concrete Homes Are Built With A 3D Printer | Insider Art

How Strong is 3D Printed Metal?

I Bought the 5 Cheapest 3D Printers on Amazon

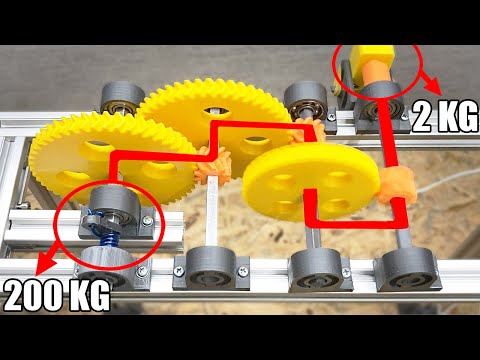

Lift Heavy Objects Using SCIENCE & 3D Printed GEARS!

Assembling and Testing the Cyborg Beast 3D Printed Prosthesis (3D Universe)

How to Calibrate a 3D Printer when the Holes come out Too Small

3D Printed Guns Are Easy To Make And Impossible To Stop (HBO)

Creality CR-30: The INFINITE 3D printer!

How bad is a $69 3D Printer?

3D printed Luigi is ready

Fastest 3D Printed Gearbox Ever.

Комментарии

0:16:23

0:16:23

0:08:25

0:08:25

0:10:12

0:10:12

0:01:00

0:01:00

0:10:25

0:10:25

0:12:23

0:12:23

0:00:58

0:00:58

0:24:27

0:24:27

0:00:20

0:00:20

0:04:35

0:04:35

0:02:44

0:02:44

0:06:38

0:06:38

0:09:49

0:09:49

0:05:33

0:05:33

0:08:29

0:08:29

0:12:32

0:12:32

0:05:42

0:05:42

0:12:01

0:12:01

0:00:59

0:00:59

0:03:50

0:03:50

0:00:28

0:00:28

0:04:20

0:04:20

0:00:30

0:00:30

0:07:01

0:07:01