filmov

tv

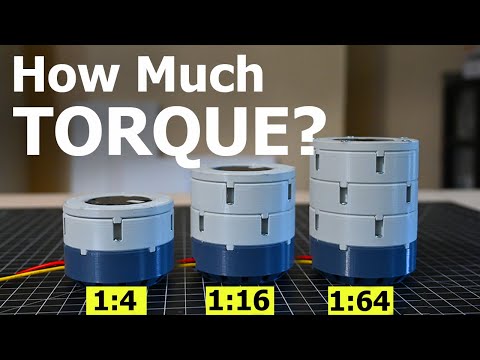

This Gearbox is So Powerful it can Pull a CAR! (3D Printed)

Показать описание

This gearbox is so strong/powerful and it can pulls a real car. All the plastics are 3d printed PLA. The gearbox uses 775 dc motor and the gear ratio of the gearbox is 98:1. The worm gear has 40 teeth. So the gear ratio in the worm gear mechanism is 40. Here there is a really high torque increase in one stage. I choose to go for helical gears on this one because they produce a lot less noice than regular spur gears and the forces on the teeth are transferred more gradually. Output shaft has a 20 mm diameter and I used 2x6004(ORS) roller bearing to support this output shaft.I was able to test the gearbox to a torque of about 43 kg*cm.During testing none of the gears broke, they were all printed in PLA.

Do not use this design in the professional field. Because you can't trust to plastic parts!

Below are all the parts I used in this project:

12V DC 775 Motor(100 Watt)

608zz bearing x3

6004 bearing x2

20 mm aluminium shaft

M8 threaded rod

Cotter pins

2x30—x4

3x50—x1

Music on the video:

Artist: Dan Henig | Track: Danger Snow

Waltz of the Flowers by Tchaikovsky

YouTube Audio Library

Frames by Pyrosion

Attribution 3.0 Unported — CC BY 3.0

Keys of Moon Music

The Road to Your Inspiration

North Edge

Do not use this design in the professional field. Because you can't trust to plastic parts!

Below are all the parts I used in this project:

12V DC 775 Motor(100 Watt)

608zz bearing x3

6004 bearing x2

20 mm aluminium shaft

M8 threaded rod

Cotter pins

2x30—x4

3x50—x1

Music on the video:

Artist: Dan Henig | Track: Danger Snow

Waltz of the Flowers by Tchaikovsky

YouTube Audio Library

Frames by Pyrosion

Attribution 3.0 Unported — CC BY 3.0

Keys of Moon Music

The Road to Your Inspiration

North Edge

Комментарии

0:06:39

0:06:39

0:06:56

0:06:56

0:07:01

0:07:01

0:04:20

0:04:20

0:01:11

0:01:11

0:11:05

0:11:05

0:05:10

0:05:10

0:09:03

0:09:03

0:00:16

0:00:16

0:10:20

0:10:20

0:08:08

0:08:08

0:00:15

0:00:15

0:10:39

0:10:39

0:08:02

0:08:02

0:00:22

0:00:22

0:06:00

0:06:00

0:10:15

0:10:15

0:10:12

0:10:12

0:09:22

0:09:22

0:00:15

0:00:15

0:05:15

0:05:15

0:08:26

0:08:26

0:07:46

0:07:46

0:06:00

0:06:00