filmov

tv

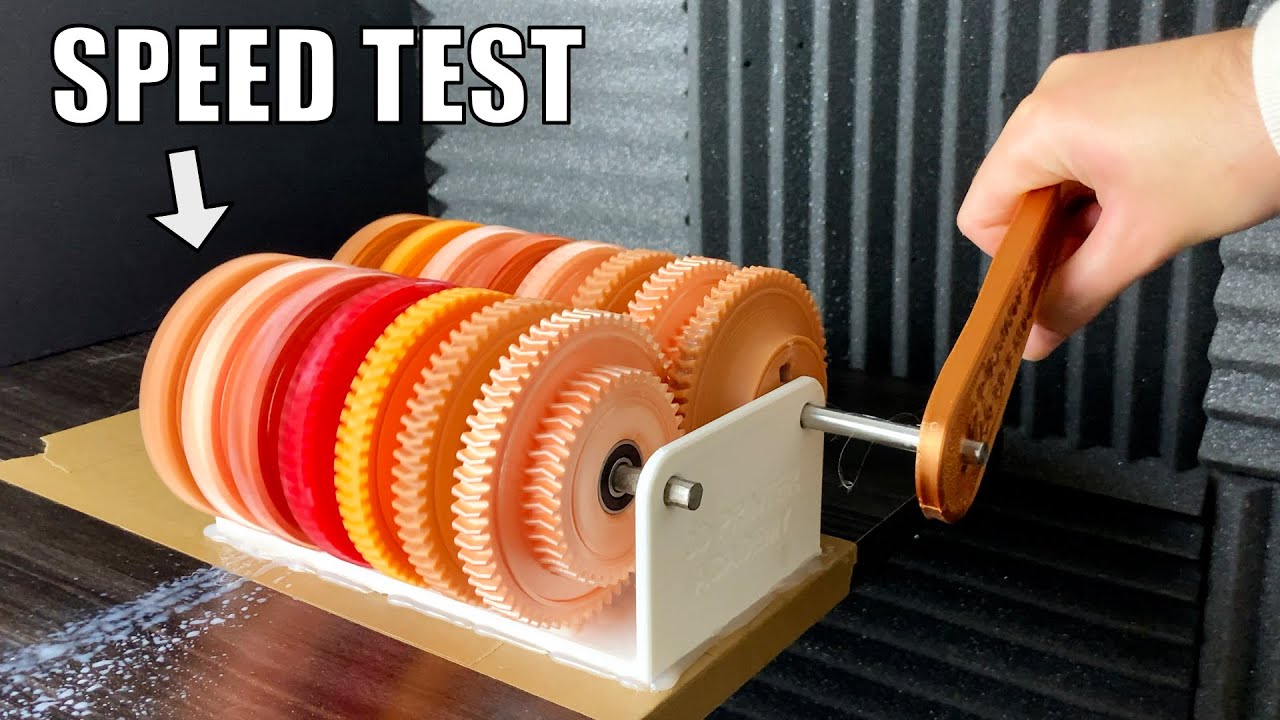

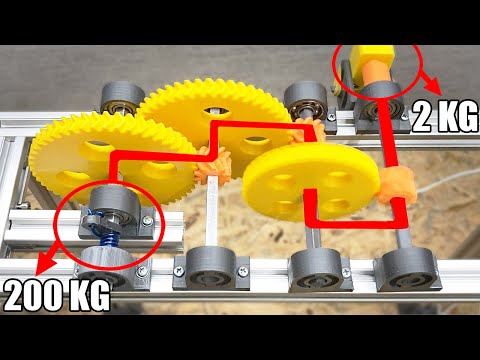

3D Printed Gearbox (Herringbone Gears) - Speed Test

Показать описание

In this 3d printed gearbox experiment we will see how these new engineering design considerations impact how well this 3d printed gearbox works. We will go through the engineering process as well and conduct a speed test to see how fast we can get the gearbox to spin.

New to 3D Printing? Start Here:

Automatic mechanical designs to 3d print yourself:

Micro Center (aka the best computer store) Links:

"Come to Micro Center for all of your Holiday shopping and get it done all in one place!

Start shopping now and beat the crowds!

Black Friday runs all month so there’s no need to rush or deal with waiting in line.

Don’t wait on shipping - buy online and pick up in store!"

If enjoyed this video please consider becoming a channel member so I can continue to make more of these videos (they are a ton of work):

#3dprinted #gearbox #microcenter #gears #3dprinting

Thank you for your support and Happy Printing!!

-Steven

New to 3D Printing? Start Here:

Automatic mechanical designs to 3d print yourself:

Micro Center (aka the best computer store) Links:

"Come to Micro Center for all of your Holiday shopping and get it done all in one place!

Start shopping now and beat the crowds!

Black Friday runs all month so there’s no need to rush or deal with waiting in line.

Don’t wait on shipping - buy online and pick up in store!"

If enjoyed this video please consider becoming a channel member so I can continue to make more of these videos (they are a ton of work):

#3dprinted #gearbox #microcenter #gears #3dprinting

Thank you for your support and Happy Printing!!

-Steven

Комментарии

0:05:10

0:05:10

0:08:01

0:08:01

0:01:10

0:01:10

0:01:00

0:01:00

0:00:28

0:00:28

0:06:56

0:06:56

0:07:01

0:07:01

0:00:18

0:00:18

0:09:59

0:09:59

0:05:42

0:05:42

0:01:12

0:01:12

0:01:11

0:01:11

0:09:28

0:09:28

0:01:23

0:01:23

0:17:49

0:17:49

0:03:12

0:03:12

0:00:52

0:00:52

0:04:01

0:04:01

0:14:21

0:14:21

0:24:43

0:24:43

0:00:16

0:00:16

0:00:49

0:00:49

0:05:31

0:05:31

0:38:17

0:38:17