filmov

tv

Gold Smelting

Показать описание

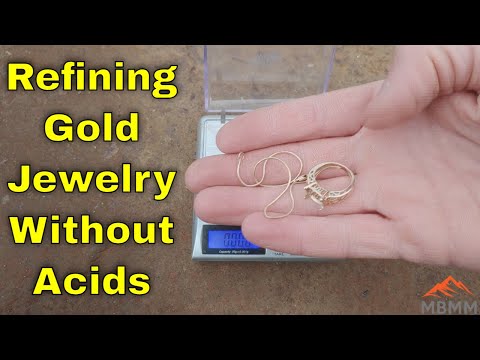

Join Jason in the smelting lab as he embarks on an exciting experiment to extract gold from sulfide ores! In this captivating video, Jason tackles the challenge of smelting gold-bearing sulfides, which require additional chemistry to release the gold from minerals like iron pyrite and other sulfides.

Watch as Jason meticulously tests a new method in his quest to optimize the gold recovery process. With careful experimentation and precise techniques, he aims to determine the most effective approach for extracting gold from sulfide-rich ores.

Delve into the intricacies of gold smelting as Jason shares his insights and strategies for maximizing gold yield. Despite facing the complexities of sulfide ores, Jason remains determined to unlock the full potential of these gold-rich samples.

Will Jason's latest experiment prove to be the breakthrough he's been seeking? Join us as we uncover the results and unravel the mysteries of gold smelting!

Don't miss out on this fascinating journey into the world of gold smelting. Like, subscribe, and hit the notification bell to stay updated on Jason's latest experiments and discoveries in the smelting lab!

AFFILIATE LINKS

What's an affiliate link? If you use our link to buy something, MBMM gets a small percentage of the money you spend. This DOES NOT mean you will spend more money using our link, you will spend the SAME AMOUNT of money while also supporting a small business and channel.

Underground Mining Equipment:

Complete Smelting Kits:

Fluxes:

Smelting Supplies:

Furnace Building Supplies:

Refining Supplies:

Filming Equipment:

Keywords: Gold Smelting, Smelting Gold, Sulfide Ores, Gold Extraction, Gold Recovery, Chemistry Experiment, Gold-bearing Sulfides, Pyrite, Precious Metals.

Hashtags: #GoldSmelting #SulfideOres #GoldExtraction #PreciousMetals #ChemistryExperiment #GoldRecovery #SmeltingLab

Watch as Jason meticulously tests a new method in his quest to optimize the gold recovery process. With careful experimentation and precise techniques, he aims to determine the most effective approach for extracting gold from sulfide-rich ores.

Delve into the intricacies of gold smelting as Jason shares his insights and strategies for maximizing gold yield. Despite facing the complexities of sulfide ores, Jason remains determined to unlock the full potential of these gold-rich samples.

Will Jason's latest experiment prove to be the breakthrough he's been seeking? Join us as we uncover the results and unravel the mysteries of gold smelting!

Don't miss out on this fascinating journey into the world of gold smelting. Like, subscribe, and hit the notification bell to stay updated on Jason's latest experiments and discoveries in the smelting lab!

AFFILIATE LINKS

What's an affiliate link? If you use our link to buy something, MBMM gets a small percentage of the money you spend. This DOES NOT mean you will spend more money using our link, you will spend the SAME AMOUNT of money while also supporting a small business and channel.

Underground Mining Equipment:

Complete Smelting Kits:

Fluxes:

Smelting Supplies:

Furnace Building Supplies:

Refining Supplies:

Filming Equipment:

Keywords: Gold Smelting, Smelting Gold, Sulfide Ores, Gold Extraction, Gold Recovery, Chemistry Experiment, Gold-bearing Sulfides, Pyrite, Precious Metals.

Hashtags: #GoldSmelting #SulfideOres #GoldExtraction #PreciousMetals #ChemistryExperiment #GoldRecovery #SmeltingLab

Комментарии

0:17:13

0:17:13

0:13:15

0:13:15

0:30:41

0:30:41

0:09:43

0:09:43

0:00:23

0:00:23

0:24:22

0:24:22

0:00:23

0:00:23

0:16:48

0:16:48

0:12:45

0:12:45

0:09:18

0:09:18

0:07:42

0:07:42

0:00:13

0:00:13

0:27:47

0:27:47

0:11:57

0:11:57

0:00:34

0:00:34

1:09:33

1:09:33

0:01:01

0:01:01

0:01:01

0:01:01

0:12:59

0:12:59

0:06:50

0:06:50

0:00:34

0:00:34

0:27:52

0:27:52

0:13:09

0:13:09

0:14:42

0:14:42