filmov

tv

Refining 14k Gold Jewelry Scrap To Precious Metals

Показать описание

Taking 14 carat gold and trying to refine it to only precious metals without using acids. This old ring and bracelet have about 63% precious metals and 37% base metals. Can I refine this scrap gold jewelry to 99% precious metals?

AFFILIATE LINKS

What's an affiliate link? If you use our link to buy something, MBMM gets a small percentage of the money you spend. This DOES NOT mean you will spend more money using our link, you will spend the SAME AMOUNT of money while also supporting a small business and channel.

Filming Equipment:

Complete Smelting Kits:

Fluxes:

Smelting Supplies:

Furnace Building Supplies:

Underground Mining Equipment:

For more info please email or call:

Phone: 360-595-4445

AFFILIATE LINKS

What's an affiliate link? If you use our link to buy something, MBMM gets a small percentage of the money you spend. This DOES NOT mean you will spend more money using our link, you will spend the SAME AMOUNT of money while also supporting a small business and channel.

Filming Equipment:

Complete Smelting Kits:

Fluxes:

Smelting Supplies:

Furnace Building Supplies:

Underground Mining Equipment:

For more info please email or call:

Phone: 360-595-4445

Refining 14k Gold Jewelry Scrap To Precious Metals

Student Gold Refining Kit

Refining Gold Scrap 14K Jewelry To .999 Fines Bar

Refining 14k Jewelry To Gold & Silver

How to refine Gold at Home

How to Refine Gold Jewellery - Inquartation Methode (DIY) P. 1

How to refine gold jewelry - Karat Scrap—1st time ever

MELTING $5,000 of 10-14K SCRAPPED AND BROKEN GOLD JEWELRY! #shorts

Scrap Jewelry Gold Refining - Cupel FAIL!

Refining and Pouring Gold #preciousmetals #art #science

Scrap Gold To High Purity Ingot In 10 Hours

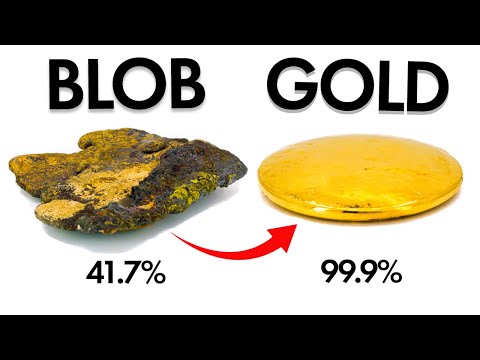

Turning a BLOB into PURE GOLD!

Turning old jewelry into pure gold bars

Refining & Recovering Gold From Rings and Jewelry

How do they melt scrap gold and turn into bar ?

PAWN SHOP Scrap Gold Melting Process Video

Sreetips How To Refine Scrap Gold Jewelry

Easy DIY Gold & Silver Refining Process At Home, No Acids. Remove Base Metals By Cupelling MBMM

How To Make 14k Gold Complete Process

Simple 14k Karat Scrap Gold Refine Part 1of2

Refining 25 Ounce Pure Gold Bar In My Garage

Pure Gold From Jeweler's Scrap in 12 Minutes

Refining Gold Filled Jewelry Five Pieces

How to melt scrap gold jewelry

Комментарии

0:13:09

0:13:09

0:03:30

0:03:30

0:24:38

0:24:38

0:01:00

0:01:00

0:05:47

0:05:47

0:06:17

0:06:17

0:14:55

0:14:55

0:01:01

0:01:01

0:08:23

0:08:23

0:00:58

0:00:58

0:27:36

0:27:36

0:18:11

0:18:11

0:31:23

0:31:23

0:14:42

0:14:42

0:02:28

0:02:28

0:01:55

0:01:55

1:18:24

1:18:24

0:06:50

0:06:50

0:33:55

0:33:55

0:42:00

0:42:00

0:03:48

0:03:48

0:12:24

0:12:24

0:37:24

0:37:24

0:02:04

0:02:04