filmov

tv

EEVblog #669 - FLIR TG165 Thermal Imager Teardown

Показать описание

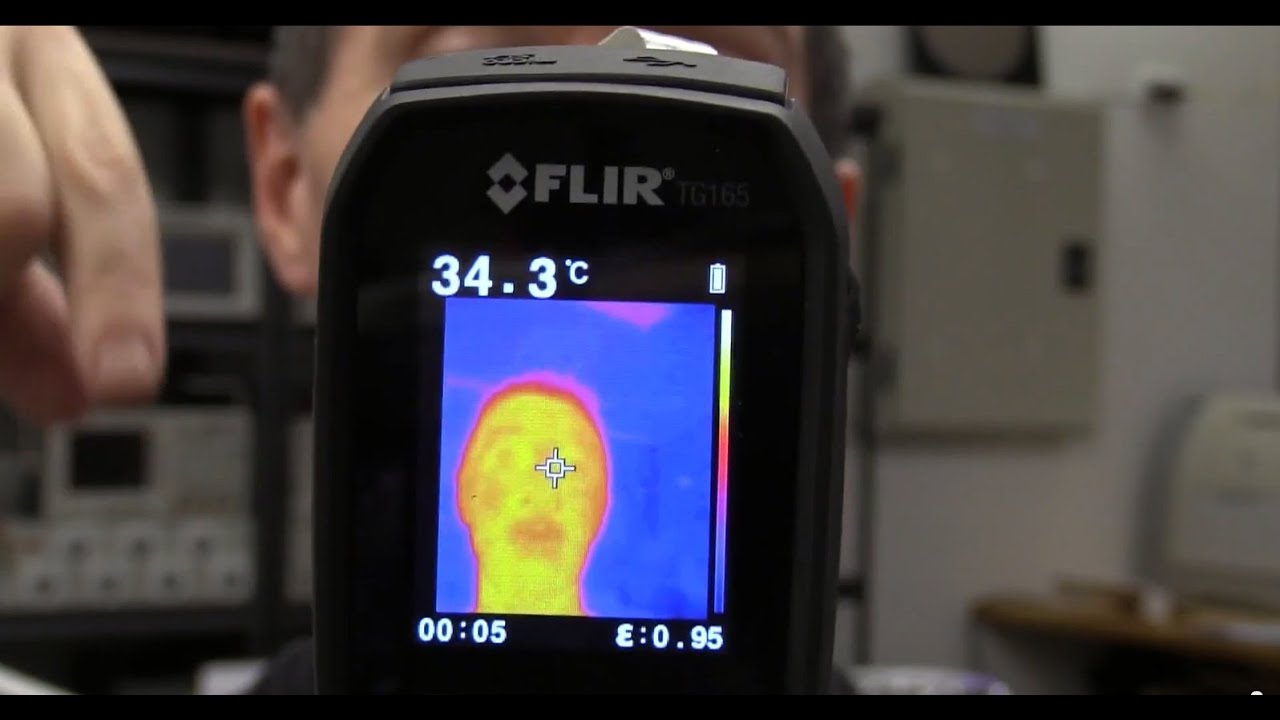

What's inside the new FLIR TG165 Visual IR Thermometer / Thermal Camera using the new Lepton sensor?

How does it compare to the FLIR ONE & FLIR E4?

Does it have a calibration shutter?

Does it have any extra capability built in ready to be hacked?

How easy is it to open? (SPOILER - it's a BASTARD!)

Datasheets:

Forum:

Teardown Photos: COMING SOON

EEVblog Amazon Store (Dave gets a cut):

Donations:

Projects:

Electronics Info Wiki:

How does it compare to the FLIR ONE & FLIR E4?

Does it have a calibration shutter?

Does it have any extra capability built in ready to be hacked?

How easy is it to open? (SPOILER - it's a BASTARD!)

Datasheets:

Forum:

Teardown Photos: COMING SOON

EEVblog Amazon Store (Dave gets a cut):

Donations:

Projects:

Electronics Info Wiki:

EEVblog #669 - FLIR TG165 Thermal Imager Teardown

EEVblog #668 - Mailbag + FLIR TG165

EEVblog #670 - FLIR TG165 Lepton Sensor Followup

FLIR TG165 Electric Duct heater not working

Thermal on a Budget - FLIR TG165 VS FLIR E8

EEVblog #988 - FLIR ETS320 Benchtop Thermal Camera Review

Trying the Flir ONE by Flir Systems

QTV #9 - FLIR TG165 vs Fluke VT04 Visual IR Thermometer / Imager

EEVblog #989 - FLIR ETS320 Thermal Camera Teardown

FLIR TG267 put to the test #noaffiliatelinks

Flir tg165 test

EEVblog #663 - Compucorp 322G Calculator Teardown

Flir TG267 Thermal camera unboxing and review

EEVblog #681 - More Solar Roadways BULLSHIT!

Tragbare Thermografiekamera zur Messung der Körpertemperatur (Deutsch)

FLIR E4 Thermal Imaging Camera teardown

FLIR at NRA 2015 and helping autism!

EEVblog #656 - Pacemaker Monitor Teardown

EEVblog #665 - Polar Wearlink Heart Rate Transmitter Teardown

EEVblog #270 - µCurrent Test Jig

PDX INST VID TG 165 HopWorks Brewery

EEVblog #773 - 80W INDUAL LED Light Teardown

Luminous beings are we!

Extreme Teardown: FLIR IR Security Camera

Комментарии

0:32:04

0:32:04

0:38:39

0:38:39

0:30:59

0:30:59

0:00:16

0:00:16

0:14:05

0:14:05

0:36:15

0:36:15

0:09:01

0:09:01

0:22:13

0:22:13

0:13:20

0:13:20

0:17:40

0:17:40

0:02:17

0:02:17

0:29:18

0:29:18

0:05:26

0:05:26

0:31:28

0:31:28

0:01:29

0:01:29

0:49:55

0:49:55

0:14:00

0:14:00

0:22:46

0:22:46

0:26:10

0:26:10

0:08:47

0:08:47

0:01:46

0:01:46

0:25:51

0:25:51

0:03:32

0:03:32

0:29:53

0:29:53