filmov

tv

Calculation of involute gears (center distance, profile shift, pressure angle, etc.)

Показать описание

In this video, we derive the basic formulas for calculating involute gears. We will mathematically determine the following parameters:

center distance, tip shortening, sum of the profile shift coefficients to obtain a certain center distance, operating pressure angle, transmission ratio, standard reference pitch circle, operating pitch circle, tip, root and base circle diameter, tip tooth clearance, (tip) tooth thickness, contact ratio

Here is the link to the Excel spreadsheet for calculating these parameters:

00:00 Construction of an involute

01:03 Definition of the involute function

02:00 Involute angle and pressure angle

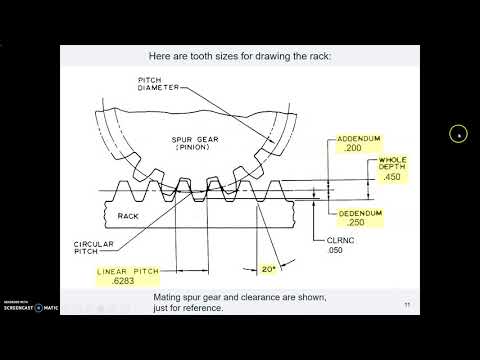

02:51 Calculating the circular tooth thickness

04:52 Calculating the involute angle alpha (pressure angle)

06:48 Calculating the tip and root circle diameter

08:03 Calculating the reference circular pitch and base pitch

09:58 Calculating the operating pressure angle

12:36 Calculating the operating pitch circle diameters

13:37 Calculating the center distance

13:57 Calculating the profile shift coefficients (for a given center distance)

15:21 V-plus gearbox, V-minus gearbox, zero-gearbox (standard gearbox)

16:24 Tooth tip clearance

18:03 Calculating the tip shortening

19:47 Line of action & line of contact

20:55 Calculating the contact ratio

23:29 Excel spreadsheet for calculation

center distance, tip shortening, sum of the profile shift coefficients to obtain a certain center distance, operating pressure angle, transmission ratio, standard reference pitch circle, operating pitch circle, tip, root and base circle diameter, tip tooth clearance, (tip) tooth thickness, contact ratio

Here is the link to the Excel spreadsheet for calculating these parameters:

00:00 Construction of an involute

01:03 Definition of the involute function

02:00 Involute angle and pressure angle

02:51 Calculating the circular tooth thickness

04:52 Calculating the involute angle alpha (pressure angle)

06:48 Calculating the tip and root circle diameter

08:03 Calculating the reference circular pitch and base pitch

09:58 Calculating the operating pressure angle

12:36 Calculating the operating pitch circle diameters

13:37 Calculating the center distance

13:57 Calculating the profile shift coefficients (for a given center distance)

15:21 V-plus gearbox, V-minus gearbox, zero-gearbox (standard gearbox)

16:24 Tooth tip clearance

18:03 Calculating the tip shortening

19:47 Line of action & line of contact

20:55 Calculating the contact ratio

23:29 Excel spreadsheet for calculation

Комментарии

0:23:55

0:23:55

0:06:56

0:06:56

0:12:31

0:12:31

0:08:01

0:08:01

0:32:37

0:32:37

0:27:46

0:27:46

0:08:13

0:08:13

0:16:27

0:16:27

0:15:36

0:15:36

0:01:12

0:01:12

0:06:27

0:06:27

0:04:53

0:04:53

0:10:39

0:10:39

0:06:24

0:06:24

0:06:35

0:06:35

0:02:29

0:02:29

0:08:27

0:08:27

0:06:32

0:06:32

0:04:41

0:04:41

0:09:38

0:09:38

0:55:17

0:55:17

0:11:31

0:11:31

0:14:39

0:14:39

0:00:51

0:00:51