filmov

tv

How to Clean or Replace any Pit Boss Auger | Pit Boss Pit Stops

Показать описание

In this tutorial Andrew will be replacing the wood pellet auger which feeds pellets into the grill. This works for replacing, cleaning, or fixing an auger jam.

An auger jam can be scary and unsettling, but the issue is thankfully pretty simple to resolve. You can do it yourself!

TOOLS:

- Phillips head (for case bolts)

- Allen wrench

- Wrench to grip auger and slide out

- Knee-high box or stool to rest hopper carriage on

STEPS:

1. Remove 8 phillips screws from beneath the carriage on the hopper.

2. Remove 2 screws on the face of the controller

3. Push the control panel through this new window to dangle beneath the hopper.

4. Remove hopper screws on the front and back. (have box or stool ready to set hopper on)

5. Place hopper on stand to keep it from pulling out the cords

6. A bolt is holding the auger into place. It has a nut on the bottom and an allen head on top. Take an allen head set to size it up, then grip the bottom with a wrench or socket to hold it still while you screw it out.

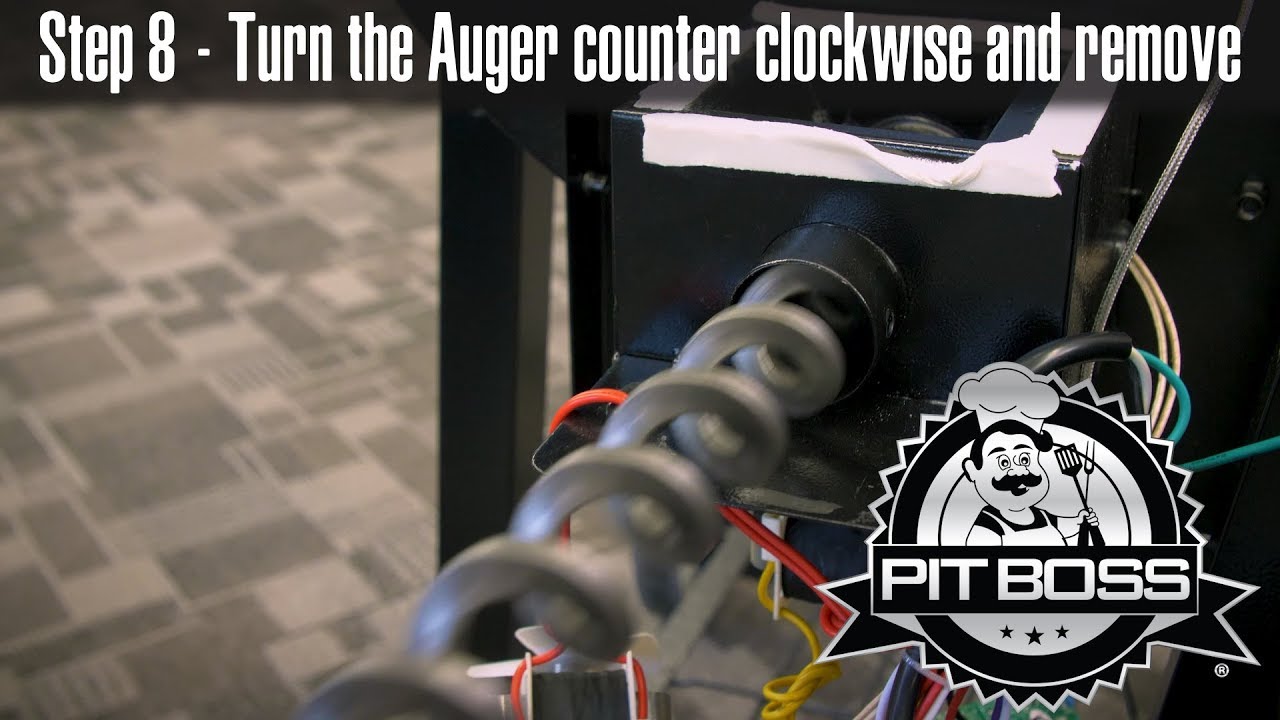

7. Remove the phillips screw holding the actual auger in place.

8. Grab the little base with a wrench, turn it counter-clockwise and slide it out.

*If you have an auger jam it will need a strong turn clockwise and a tough pull. Don't be scared to put your back into it.

9 . Here you can replace or clean the Auger. Putting everything back together is as simple as doing the steps in reverse order.

If you have any further issues, contact Pit Boss support for help!

877-303-3134

OR join the Pit Boss Owner's group on Facbook to chat, learn and more

An auger jam can be scary and unsettling, but the issue is thankfully pretty simple to resolve. You can do it yourself!

TOOLS:

- Phillips head (for case bolts)

- Allen wrench

- Wrench to grip auger and slide out

- Knee-high box or stool to rest hopper carriage on

STEPS:

1. Remove 8 phillips screws from beneath the carriage on the hopper.

2. Remove 2 screws on the face of the controller

3. Push the control panel through this new window to dangle beneath the hopper.

4. Remove hopper screws on the front and back. (have box or stool ready to set hopper on)

5. Place hopper on stand to keep it from pulling out the cords

6. A bolt is holding the auger into place. It has a nut on the bottom and an allen head on top. Take an allen head set to size it up, then grip the bottom with a wrench or socket to hold it still while you screw it out.

7. Remove the phillips screw holding the actual auger in place.

8. Grab the little base with a wrench, turn it counter-clockwise and slide it out.

*If you have an auger jam it will need a strong turn clockwise and a tough pull. Don't be scared to put your back into it.

9 . Here you can replace or clean the Auger. Putting everything back together is as simple as doing the steps in reverse order.

If you have any further issues, contact Pit Boss support for help!

877-303-3134

OR join the Pit Boss Owner's group on Facbook to chat, learn and more

Комментарии

0:03:01

0:03:01

0:02:04

0:02:04

0:10:57

0:10:57

0:02:27

0:02:27

0:00:49

0:00:49

0:00:36

0:00:36

0:02:28

0:02:28

0:05:00

0:05:00

0:01:07

0:01:07

0:01:39

0:01:39

0:03:09

0:03:09

0:05:36

0:05:36

0:02:06

0:02:06

0:01:19

0:01:19

0:01:09

0:01:09

0:06:08

0:06:08

0:03:43

0:03:43

0:03:22

0:03:22

0:01:56

0:01:56

0:02:00

0:02:00

0:15:44

0:15:44

0:06:45

0:06:45

0:14:57

0:14:57

0:04:27

0:04:27