filmov

tv

Introduction to Stepper Motors for 3D Printing - The Basics you probably need to know - Episode 1

Показать описание

Stepper motors! Pretty important for 3d printers, right? But does anyone understand how they work?

Me neither, but armed with a little knowledge and a lot of Wikipedia, and maybe some long nose pliers - we'll get to the bottom of this.

Join me on a 3 part voyage of discovery into what's inside them, what makes them tick (hah), how you drive them, and eventually we'll get on to how you shut them up!

Part one (this part) is about what they are, why they are, and taking them to bits and watching them move. Fascinating.

Any comments please let me know, I'm sure I've missed points, made mistakes on this one, corrections will go here or be picked up in the next episode.

Waste: None. Nothing.

No steppers..okay maybe one stepper was harmed in the making of this video. For science.

**** Please consider supporting the channel to allow me to do more, and better stuff! ****

Me neither, but armed with a little knowledge and a lot of Wikipedia, and maybe some long nose pliers - we'll get to the bottom of this.

Join me on a 3 part voyage of discovery into what's inside them, what makes them tick (hah), how you drive them, and eventually we'll get on to how you shut them up!

Part one (this part) is about what they are, why they are, and taking them to bits and watching them move. Fascinating.

Any comments please let me know, I'm sure I've missed points, made mistakes on this one, corrections will go here or be picked up in the next episode.

Waste: None. Nothing.

No steppers..okay maybe one stepper was harmed in the making of this video. For science.

**** Please consider supporting the channel to allow me to do more, and better stuff! ****

What is a Stepper Motor?

Introduction to Stepper Motors for 3D Printing - The Basics you probably need to know - Episode 1

Electronic Basics #24: Stepper Motors and how to use them

Stepper Motors and Arduino - The Ultimate Guide

Arduino Basics Intro to Stepper Motors

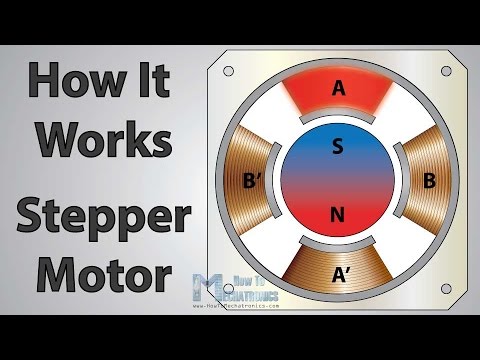

Stepper Motor - How It Works

Introduction To Stepper Motors

stepper motor | introduction |

Stepper Motor Forward and Reverse Control Using PLC & HMI

Servo vs Stepper Motors

Introduction to Servo Motors and Stepper Motors

Introduction To Stepper Motor Motion Control. Pulse And Direction.

Stepper Motors with Arduino - Controlling Bipolar & Unipolar stepper motors

Intro to Stepper Motors

How does a Stepper Motor work? Full lecture

Big Stepper Motors with Arduino

Introduction to motors. DC, Servo & Stepper.

Stepper Motor Introduction | Special Electrical Machines

Arduino Beginners Getting Started With NEMA 17 Stepper Motor and The L298N Motor Driver Module

Stepper Motor Introduction

Stepper motor driver basics

LinuxCNC for the Hobbyist - 011 - Introduction to Stepper Motors

What Is A Stepper Motor? Watch This!

Leadshine Integrated Stepper Motors Brief Introduction

Комментарии

0:02:42

0:02:42

0:11:00

0:11:00

0:06:47

0:06:47

0:29:57

0:29:57

0:09:00

0:09:00

0:04:43

0:04:43

0:07:54

0:07:54

0:08:08

0:08:08

0:04:06

0:04:06

0:02:32

0:02:32

0:08:20

0:08:20

0:08:10

0:08:10

0:50:22

0:50:22

0:02:00

0:02:00

0:07:24

0:07:24

0:29:43

0:29:43

0:12:33

0:12:33

0:09:35

0:09:35

0:19:12

0:19:12

0:09:16

0:09:16

0:06:53

0:06:53

0:11:36

0:11:36

0:00:30

0:00:30

0:02:46

0:02:46