filmov

tv

How to Fit Copper Pipes | Ask This Old House

Показать описание

In this video, Ask This Old House plumbing & heating expert Richard Tretheway shows host Kevin O’Connor several methods for making solid, watertight connections, both with solder and without.

Kevin O’Connor meets plumbing and heating expert Richard Tretheway for a primer on how to fit copper pipes. Richard shows Kevin some of the most common methods for plumbing connections, including soldered and several types of solderless connections.

Soldered Connections

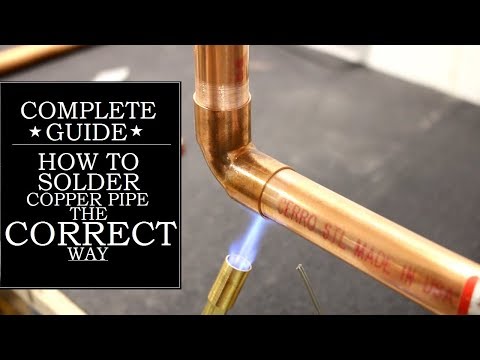

In most settings, soldered connections are still the plumber’s preferred method of fitting copper pipes. By applying pipe flux and heating the joint, solder flows between the fitting and the pipe to create a watertight seal. While this is an economical method for soldering pipes, there can be issues with using torches near framing lumber, meaning some plumbing installers might opt for solderless fittings.

Pro-Set or Clamp-on Fittings

Pro-Set fittings clamp onto the copper pipe. These fittings are pre-made, and instead of solder, they have an o-ring inside. Using a special tool, the installer can squeeze the fittings onto the pipe, creating a solid structural connection with the o-ring making it watertight. These joints are fast and strong but require a special and expensive tool to crimp them in place.

Push-on Fittings

For another method of solderless connection which might be a bit more homeowner-friendly is push-on fittings. These fittings feature an o-ring and a stainless steel ring with angled teeth. Once the installer pushes these fittings onto the pipe, the teeth bite into the copper, and the o-ring seals around the pipe to create a strong, watertight connection. These fittings are also easy to remove with an inexpensive tool. The downside of these fittings is they’re expensive and don’t provide any structural strength, requiring more hangers than a traditional fitting.

Compression Fittings

Compression fittings are some of the oldest solderless connections, and they work by compressing a small brass ring between the fitting and a nut. When the installer tightens the nut, the brass ring wedges against the pipe to create a watertight connection. These fittings are more affordable than push-on or clamp-on fittings, but they can be a bit more finicky to install as the user needs to be able to turn two wrenches at once for a perfect seal.

Solder Is Here To Stay

Even with the invention of these solderless connections, Richard believes solder isn’t going anywhere anytime soon. As the most affordable form of plumbing connection, plumbers will continue to rely on solder when they need to make quick connections or when they don’t have a solderless fitting on hand.

About Ask This Old House TV:

From the makers of This Old House, America’s first and most trusted home improvement show, Ask This Old House answers the steady stream of home improvement questions asked by viewers across the United States. Covering topics from landscaping to electrical to HVAC and plumbing to painting and more. Ask This Old House features the experts from This Old House, including general contractor Tom Silva, plumbing and heating expert Richard Trethewey, landscape contractor Jenn Nawada, master carpenter Norm Abram, and host Kevin O’Connor. Ask This Old House helps you protect and preserve your greatest investment—your home.

Follow This Old House and Ask This Old House:

How to Fit Copper Pipes | Ask This Old House

Kevin O’Connor meets plumbing and heating expert Richard Tretheway for a primer on how to fit copper pipes. Richard shows Kevin some of the most common methods for plumbing connections, including soldered and several types of solderless connections.

Soldered Connections

In most settings, soldered connections are still the plumber’s preferred method of fitting copper pipes. By applying pipe flux and heating the joint, solder flows between the fitting and the pipe to create a watertight seal. While this is an economical method for soldering pipes, there can be issues with using torches near framing lumber, meaning some plumbing installers might opt for solderless fittings.

Pro-Set or Clamp-on Fittings

Pro-Set fittings clamp onto the copper pipe. These fittings are pre-made, and instead of solder, they have an o-ring inside. Using a special tool, the installer can squeeze the fittings onto the pipe, creating a solid structural connection with the o-ring making it watertight. These joints are fast and strong but require a special and expensive tool to crimp them in place.

Push-on Fittings

For another method of solderless connection which might be a bit more homeowner-friendly is push-on fittings. These fittings feature an o-ring and a stainless steel ring with angled teeth. Once the installer pushes these fittings onto the pipe, the teeth bite into the copper, and the o-ring seals around the pipe to create a strong, watertight connection. These fittings are also easy to remove with an inexpensive tool. The downside of these fittings is they’re expensive and don’t provide any structural strength, requiring more hangers than a traditional fitting.

Compression Fittings

Compression fittings are some of the oldest solderless connections, and they work by compressing a small brass ring between the fitting and a nut. When the installer tightens the nut, the brass ring wedges against the pipe to create a watertight connection. These fittings are more affordable than push-on or clamp-on fittings, but they can be a bit more finicky to install as the user needs to be able to turn two wrenches at once for a perfect seal.

Solder Is Here To Stay

Even with the invention of these solderless connections, Richard believes solder isn’t going anywhere anytime soon. As the most affordable form of plumbing connection, plumbers will continue to rely on solder when they need to make quick connections or when they don’t have a solderless fitting on hand.

About Ask This Old House TV:

From the makers of This Old House, America’s first and most trusted home improvement show, Ask This Old House answers the steady stream of home improvement questions asked by viewers across the United States. Covering topics from landscaping to electrical to HVAC and plumbing to painting and more. Ask This Old House features the experts from This Old House, including general contractor Tom Silva, plumbing and heating expert Richard Trethewey, landscape contractor Jenn Nawada, master carpenter Norm Abram, and host Kevin O’Connor. Ask This Old House helps you protect and preserve your greatest investment—your home.

Follow This Old House and Ask This Old House:

How to Fit Copper Pipes | Ask This Old House

Комментарии

0:05:54

0:05:54

0:05:05

0:05:05

0:11:02

0:11:02

0:20:39

0:20:39

0:06:26

0:06:26

0:02:40

0:02:40

0:02:07

0:02:07

0:11:52

0:11:52

0:00:34

0:00:34

0:11:56

0:11:56

0:02:37

0:02:37

0:05:06

0:05:06

0:02:50

0:02:50

0:04:24

0:04:24

0:03:03

0:03:03

0:11:49

0:11:49

0:01:29

0:01:29

0:04:31

0:04:31

0:05:42

0:05:42

0:04:04

0:04:04

0:12:21

0:12:21

0:03:22

0:03:22

0:00:31

0:00:31

0:01:04

0:01:04