filmov

tv

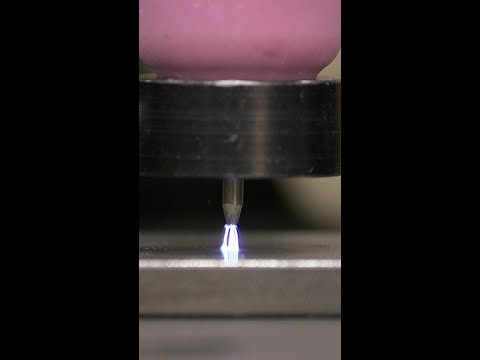

Pulse TIG Project

Показать описание

Sometimes pulse makes a big difference. But sometimes it doesn't seem to help all that much at all.

I like to mess around with it here and there to see what works.

One application where high speed pulse settings seem to really help is when welding on an edge....or near and edge.

These parts are going to be used in another video coming soon and I might even do a bit of tig brazing with silicon bronze to make things interesting.

Follow me on social media to see what I’m up to:

Join the discussion with thousands of welders at the Welding Tips & Tricks forum

Pulse TIG Project

TIG WELDING HOW TO - PULSE WELDING! TIG WELDING SETTINGS

Pulse Tig Welding Aluminum - JIMBOS GARAGE

Build a TIG welder pulser add-on for $10. Cheap and Easy.

Aluminium Pulse Tig Welding

EXPLAINED: DC Pulse TIG Settings and Setup | Everlast Welders

I SCREW UP on camera doing a TIG pulse welding demo😂

TIG WELDING PULSE WITH A FOOTPEDAL - TIG WELDING TECHNIQUES

Exploring the YesWelder DP200 Flux Core Welding Feature

Pulse Tig Settings for Outside Corner

4 Tips To Make YOU a BETTER TIG Welder

The FIRST 3 things to learn tig welding.

Lift TIG Welding - YesWelder FIRSTESS™ MP200 5-in-1 Welder & Cutter

CanaWeld Review! 201 - Pulse Tig Welding Machine!

TIG Welding Aluminum

Stop doing this to yourself tig welding! Follow this tip! #shorts

a WARNING to all beginner tig welders.

Beginner TIG welders NEED to know this...

Manual Pulse Tig welding Techniques animation |Tig welding pulse setting and how to pulse weld steel

Affordable Tig Welder Project

Crazy Welding Skills on Display at WorldSkills 2022 Special Edition

Diy Tig Welding With High Frequency Start And Pulae Modulation

HOW TO MIG LIKE TIG WELD (Stacking Dimes) W/ OVERKILLRACINGANDCHASSIS w/ *Tips and Techniques*

TIG Welding: Pulse Vs No Pulse

Комментарии

0:05:35

0:05:35

0:21:39

0:21:39

0:07:00

0:07:00

0:14:14

0:14:14

0:01:14

0:01:14

0:07:33

0:07:33

0:07:21

0:07:21

0:21:52

0:21:52

0:04:36

0:04:36

0:09:35

0:09:35

0:07:26

0:07:26

0:10:23

0:10:23

0:02:43

0:02:43

0:30:34

0:30:34

0:05:14

0:05:14

0:00:59

0:00:59

0:10:57

0:10:57

0:00:18

0:00:18

0:02:13

0:02:13

0:09:31

0:09:31

0:12:58

0:12:58

0:00:26

0:00:26

0:06:20

0:06:20

0:09:11

0:09:11