filmov

tv

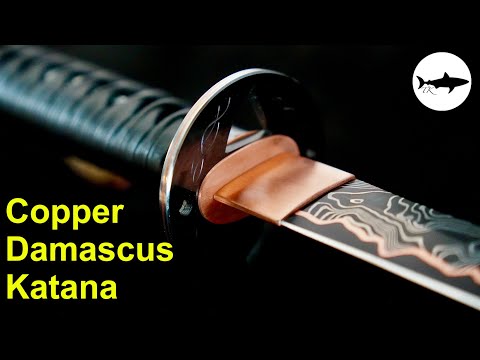

Making an $8000 Damascus Katana

Показать описание

This build was a ton of fun! There were so many things that I made for the first time, and I poured my soul into every aspect of this build. I hope you enjoyed the video, and I hope I brought a smile to your face :)

Check out my links below:

My Instagram: @jhublades

Joey's Instagram: @photosby_hu

Shop Equipment I Recommend:

Music: Epidemic Sound

My Shop Equipment:

Forging Press: 25 Ton Press from Coal Iron Works

Forge: 2-Burner Habanero from Chile Forge

Grinder: KMG-TX from Beaumont Metalworks

Anvil: 365lb Sichelschmidt und Schlasse

Heat Treating Oven: Paragon KM36T

CHAPTERS:

---------------------------------------------------------

0:00 - Intro

0:21 - Forging the Damascus

8:34 - Forging out the Blade

12:46 - Grinding and Normalizing

16:30 - Factor 75

17:39 - Quenching and Straightening

19:48 - Pain

20:03 - Forging and Straightening the Second Blade

22:43 - Final Grinding and Polishing

28:42 - Habaki

33:40 - Seppa and Tsuba (Spacer and Guard)

37:13 - Tsuka (Handle)

41:56 - Fuchi and Kashira (Handle Caps)

46:39 - Shaping Fittings

48:09 - Saya (Sheath)

56:08 - Rayskin Wrap

58:51 - Koiguchi

1:00:38 - Saya Base Coat

1:01:45 - Polishing the Tsuba

1:03:02 - Menuki (Handle Ornaments)

1:04:29 - Ito-Wrap and Mekugi Pin

1:08:46 - Etching my Maker's Mark

1:09:37 - Etching the Damascus Pattern

1:12:46 - Painting the Saya/Finishing Touches

1:13:45 - Final Reveal

1:15:15 - Sharpening and Testing

#blacksmith #damascus #knife #forging

Комментарии

1:16:34

1:16:34

0:26:06

0:26:06

1:01:44

1:01:44

0:00:17

0:00:17

0:00:16

0:00:16

0:09:47

0:09:47

0:01:00

0:01:00

0:43:33

0:43:33

0:00:21

0:00:21

0:00:52

0:00:52

0:00:28

0:00:28

0:00:32

0:00:32

0:00:33

0:00:33

0:36:50

0:36:50

0:00:18

0:00:18

0:22:19

0:22:19

0:42:11

0:42:11

0:10:05

0:10:05

0:00:20

0:00:20

0:00:17

0:00:17

0:00:15

0:00:15

0:00:16

0:00:16

0:00:59

0:00:59

0:00:16

0:00:16