filmov

tv

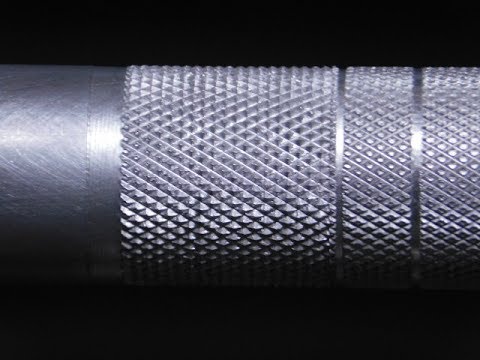

Square Knurling with no Knurling tool?

Показать описание

Want to create Square Knurling but have no Knurling tool? Today I show a technique for creating square knurling on a shop made hand wheel that does not require the use of a knurling tool.

Spindle Indexer video;

Support the channel;

Buy project plans, 3D printable items and merch!

Check me out on instagram;

Timestamps

0:00 Introduction

1:25 Making a hand wheel

1:47 Making the nut

2:15 Knurling

2:44 Square Knurling

3:17 Indexing head

3:50 Clean up surfaces

4:08 Cutting the horizontal grooves

4:57 Cutting the radial grooves

5:42 Facing/Deburring

6:09 Decorative recess

6:32 Parting off

7:55 Laser engraving

8:02 Finished knurled handwheel

Spindle Indexer video;

Support the channel;

Buy project plans, 3D printable items and merch!

Check me out on instagram;

Timestamps

0:00 Introduction

1:25 Making a hand wheel

1:47 Making the nut

2:15 Knurling

2:44 Square Knurling

3:17 Indexing head

3:50 Clean up surfaces

4:08 Cutting the horizontal grooves

4:57 Cutting the radial grooves

5:42 Facing/Deburring

6:09 Decorative recess

6:32 Parting off

7:55 Laser engraving

8:02 Finished knurled handwheel

Square Knurling with no Knurling tool?

Making the KING of All Knurling Tools (Part 1) || INHERITANCE MACHINING

Shaping and knurling on a cnc mill !!

Home Machine Shop Tool Making - Machining A Set Of Vintage Style Rope Knurls

Knurling from two Sides - The Perfect Knurling

CNC knurling without a knurling tool

Leveling Up My Knurling Game: Making a next level Knurling Tool!

Knurling and a Few Things you Should Know

Repairing a knurling tool part1

cnc knurling program in fanuc #cnc #gautam

how to knurl on the lathe all types of knurling

knurling tool part 1 of 2

How to knurl with a pinch type knurling tool, the basic theory, part 2

Homemade Knurling Jig

Hemingway Knurling tool build Part 1 The Body

Knurling on a lathe

Making of a special cut knurling tool

Face knurling a 22' plate on a lathe VS on a mill

How to knurl with a pinch type knurling tool, one pass, Part one

WORKSHOP TOPICS - THREE TYPES OF KNURLING TOOLS

Clamp Knurling Tool, Body, Four Ways to Machine the Outer Contour

Turning an Eccentric Cam on the Lathe: Hemingway Sensitive Knurling Tool Build - Part 5

Conveyor knurling roller's processing technology from on lathe machine

Knurling on a metal lathe

Комментарии

0:09:32

0:09:32

0:22:11

0:22:11

0:03:24

0:03:24

0:12:05

0:12:05

0:06:29

0:06:29

0:18:10

0:18:10

0:26:10

0:26:10

0:35:37

0:35:37

0:35:01

0:35:01

0:00:32

0:00:32

0:13:38

0:13:38

0:23:53

0:23:53

0:14:25

0:14:25

0:13:07

0:13:07

0:13:26

0:13:26

0:07:01

0:07:01

0:14:40

0:14:40

0:03:42

0:03:42

0:15:03

0:15:03

0:07:40

0:07:40

0:24:36

0:24:36

0:20:25

0:20:25

0:04:18

0:04:18

0:08:41

0:08:41