filmov

tv

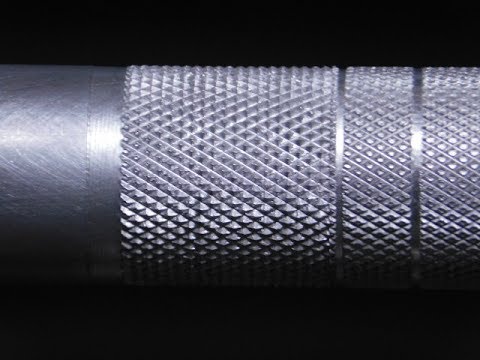

Knurling and a Few Things you Should Know

Показать описание

This video tells about the various types of knurling wheels and the best applications. I'll show a couple types of good holders and tell you a trick for better results. Take a look.

Knurling and a Few Things you Should Know

Master the Art of Knurling: Tools, Techniques, and Aluminum Knurling on a Lathe

Knurling tool in action

How to process straight knurling?

QUICK Knurling Tools at Penn Tool Co.

My first time cut knurling on a CNC lathe. The setup

What kind of the knurling process that you prefer | CNC SMARTLATHE

Making the KING of All Knurling Tools (Part 1) || INHERITANCE MACHINING

Making Knurling on a Lathe #shorts

The Right Amount of Knurling

Knurling Die #diy

Don't underestimate this knurling tool #cncmachine #tornado #cnc

Cnc Diamond knurling #shorts

Knurling Design | Mechanical Engineering | Working | #shorts

Straight knurling a chonky boy #knurling #machinist #machining #machinisttools #lathe #knurl

Shop made Knurling Tool

How is the performance of our CNC lathe on knurling? | STS-GT series

How to use CNC lathe parts knurling | Smart CNC lathe

|| Diamond Knurling in Lathe #shorts I|

Cut Knurling Brass

Big Shaft/Rod Knurling on Lathe Machine

CNC turning. Knurling process.#cncmachining #cnc #gear #Gearparts #machining #knurling

Knurling roller machining. Futian Roller focuses on steel roller, rubber roller, idler rolls, etc.

#knurling || #How to make #knurling Cnc Turning Machine || #Short Video ||

Комментарии

0:35:37

0:35:37

0:00:16

0:00:16

0:00:17

0:00:17

0:00:09

0:00:09

0:00:30

0:00:30

0:00:14

0:00:14

0:00:13

0:00:13

0:22:11

0:22:11

0:00:20

0:00:20

0:00:06

0:00:06

0:00:05

0:00:05

0:00:26

0:00:26

0:00:13

0:00:13

0:00:16

0:00:16

0:00:21

0:00:21

0:00:23

0:00:23

0:00:10

0:00:10

0:00:10

0:00:10

0:00:12

0:00:12

0:00:13

0:00:13

0:00:19

0:00:19

0:00:13

0:00:13

0:00:12

0:00:12

0:00:14

0:00:14