filmov

tv

Labscope Relative Compression Testing

Показать описание

PAY IT FORWARD . . . Please help me keep all my resources FREE for everyone to learn from and use. DONATE any amount here

Labscope Relative Compression Testing

How To Do A Relative Compression Test With Lab Scope - (Snap-on Modis Edge Lab Scope)

Using the Autel Ultra lab scope (Relative Compression Test)

How to perform a compression test with a lab scope (Quick Tips)

Compression tests - Conventional vs. Labscope

Relative Compression Test - Diagnostic Quick Tips | Snap-on Training Solutions®

Garage Gurus | How to Perform a Relative Compression Test with a Scope

PERFORMING RELATIVE COMPRESSION WITHOUT AN AMP CLAMP

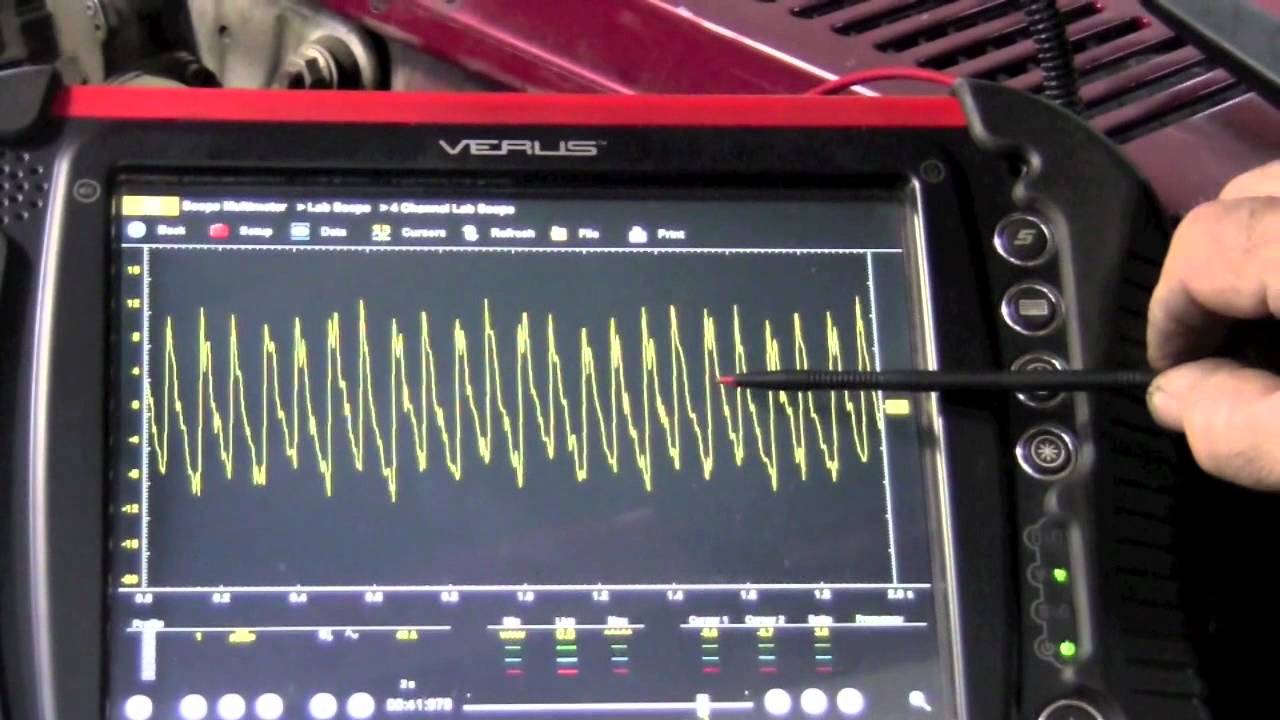

How to perform a compression test with a scope (Verus-Vantage)

Relative Compression Test with a DSO (Digital Storage Oscilloscope)

Relative Compression with Battery Voltage Check

Relative compression test without an amp clamp

PicoScope Basics: Relative Compression Testing

Relative compression testing with a Picoscope

relative compression set up with low amp clamp

DONT TRUST THE RELATIVE COMPRESSION TEST!

Relative Compression Snap On ZEUS Dorman Training G Truglia Pete Meier and Swede Oun

Relative Compression Test On A Snap On Scope #automotive #carmechanic #mechanic #snapon #pico

Compression testing with Frank Massey from ADS - Episode 2: Relative compression test

The Relative Compression Test - Explained

How to Perform a Relative Compression Test on an Engine

Compression Test with a Scope [PicoScope, Autel MP408, Micsig, & Autel Ultra]

How to perform a relative compression test (without a amp clamp)

How to Diagnose an Engine Misfire, Relative Compression Test

Комментарии

0:07:30

0:07:30

0:04:29

0:04:29

0:15:25

0:15:25

0:05:38

0:05:38

0:20:13

0:20:13

0:02:57

0:02:57

0:06:09

0:06:09

0:08:16

0:08:16

0:12:58

0:12:58

0:02:25

0:02:25

0:09:12

0:09:12

0:02:40

0:02:40

0:11:50

0:11:50

0:14:03

0:14:03

0:12:07

0:12:07

0:08:53

0:08:53

0:07:42

0:07:42

0:05:21

0:05:21

0:04:44

0:04:44

0:11:34

0:11:34

0:07:35

0:07:35

0:25:16

0:25:16

0:06:51

0:06:51

0:05:20

0:05:20