filmov

tv

DONT TRUST THE RELATIVE COMPRESSION TEST!

Показать описание

Thank you all for tuning in to Super Mario Diagnostics!

DONT TRUST THE RELATIVE COMPRESSION TEST!

Relative Compression Test Misled Me! (user error)

xavier memes #memes

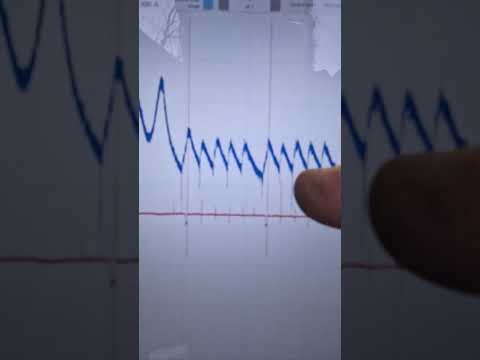

Using the Autel Ultra lab scope (Relative Compression Test)

Relative compression test on a poorly Smart Car

Misfiring Jeep Relative Compression Test #shorts

Misfire diagnostic, gasoline V8 engine relative compression test= good

Can YOU Fix It Part 4 Relative Compression Test

How to perform a compression test with a lab scope (Quick Tips)

2013 Grand Caravan - Dead Cylinder! Relative Compression Test!

Comment yes for more body language videos! #selfhelp #personaldevelopment #selfimprovement

8 Signs You Have A Toxic Sibling

How much does B.TECH pay?

Relative Compression Test on 2002 Ford Crown Victoria

Do YOU Want To Know Why WE Don't Use Sleeve Pullers?

DO NOT SQUARE THE CLUB FACE AND START IT IS LIKE THIS INSTEAD! (CHEAT METHOD)

▶️ Real hero ac technician 🤟#husainelectrical #viral #shorts #shortvideo #viralvideo #viralshorts...

Does Ford's New Dual Fuel Injection 3.5L Ecoboost Engine Really Fix the Carbon Build Up Issue?

Can a $60 scope do what a $1600 scope does for automotive diagnostics?

Dodge Ram Engine Diagnosis... Doesn't Take Long

GOLF: Why Amateur Golfers Can't Hit Driver

Principles of Fracture Fixation | Orthopedic Basics

Mixing Classical Music: what you don't suspect!

The Incredible Strength of Bolted Joints

Комментарии

0:08:53

0:08:53

0:09:17

0:09:17

0:00:06

0:00:06

0:15:25

0:15:25

0:00:59

0:00:59

0:01:00

0:01:00

0:00:06

0:00:06

0:08:01

0:08:01

0:05:38

0:05:38

0:08:02

0:08:02

0:00:22

0:00:22

0:04:42

0:04:42

0:00:34

0:00:34

0:00:09

0:00:09

0:15:33

0:15:33

0:06:00

0:06:00

0:00:29

0:00:29

0:10:02

0:10:02

0:52:56

0:52:56

0:04:54

0:04:54

0:11:58

0:11:58

0:29:34

0:29:34

0:15:24

0:15:24

0:17:58

0:17:58