filmov

tv

Rule #1 for Programming PLCs

Показать описание

This might not be what everyone wants to hear...however my goal is to encourage programmers in the correct direction for the sake of their careers. The engineer must go to the process...not expect the process to come to them...it is about the process and not about us, the engineers.

Rule #1 for Programming PLCs

Senior Programmers vs Junior Developers #shorts

10 Basic Programming Rule 1

What a typical day of a programmer can look like 💻 #coder #softwareengineer

PLC Laws #56 - RULE 1: PLUG IT IN. RULE 2: TURN IT ON. THIS SOLVES...

PLC Ladder Logic Basics For Beginners With A Working Conveyor

What is a PLC? (90 sec)

Tank Level Control with PLC ladder Logic || Animated || PLC Programming tutorials for beginners

PLC Programmers There Are Rules - An Introduction

PLC Laws #1 - Don't Overcomplicate

Introduction of Ladder Programming In PLC.|| Ladder Programming Of AND,OR,NAND,NOR Gates.

PLC | DCS | Programming Basic Rules

PLC Programming Tutorial Tips and Tricks for Beginners

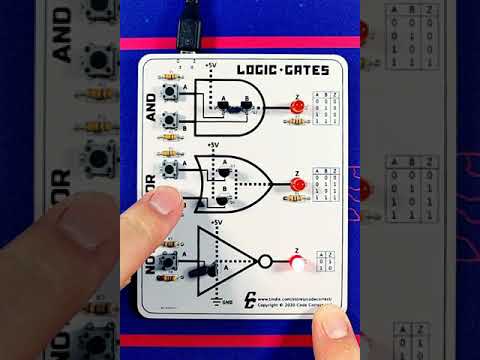

Logic Gates Learning Kit #2 - Transistor Demo

Ladder Logic Examples - PLC Programming Example for Practice

1st yr. Vs Final yr. MBBS student 🔥🤯#shorts #neet

What is PLC?# PLC programming# Tamil explained# Shorts # Sathish Kumar.

plc ladder logic programming rules

How to Convert a Basic Wiring Diagram to a PLC Program

PLC series #1|| Ladder program for AND ,OR logic

plc programmer

PLC Laws #9 - WHEN POWERING UP A PLC THE FIRST TIME

Boolean Logic to PLC Function Blocks | Fundamentals

PLC Series Chapter 1 - Introduction

Комментарии

0:33:00

0:33:00

0:00:34

0:00:34

0:06:54

0:06:54

0:00:10

0:00:10

0:00:06

0:00:06

0:06:35

0:06:35

0:01:39

0:01:39

0:03:58

0:03:58

0:15:34

0:15:34

0:00:07

0:00:07

0:05:40

0:05:40

0:12:52

0:12:52

0:04:59

0:04:59

0:00:23

0:00:23

0:11:16

0:11:16

0:00:20

0:00:20

0:00:51

0:00:51

0:06:20

0:06:20

0:07:03

0:07:03

0:09:27

0:09:27

0:00:05

0:00:05

0:00:07

0:00:07

0:06:54

0:06:54

0:38:27

0:38:27