filmov

tv

Ladder Logic Examples - PLC Programming Example for Practice

Показать описание

In this video, we will learn the ladder logic examples and PLC programming example for practice.

## Free PLC and SCADA Training Courses ##

1. Free Siemens PLC Training Course

2. Free Allen Bradley PLC Ladder Logic Training Course

3. Free InTouch SCADA Tutorial Course for Beginners

4. Free WinCC SCADA Training Course

#PLC #LadderLogicExamples #PLCprogrammingExample

## Free PLC and SCADA Training Courses ##

1. Free Siemens PLC Training Course

2. Free Allen Bradley PLC Ladder Logic Training Course

3. Free InTouch SCADA Tutorial Course for Beginners

4. Free WinCC SCADA Training Course

#PLC #LadderLogicExamples #PLCprogrammingExample

Ladder Logic Examples - PLC Programming Example for Practice

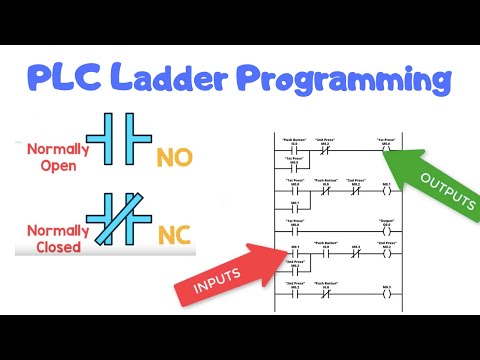

PLC Ladder programming #1 | Learn under 5 min | NO NC contacts | AND gate logic

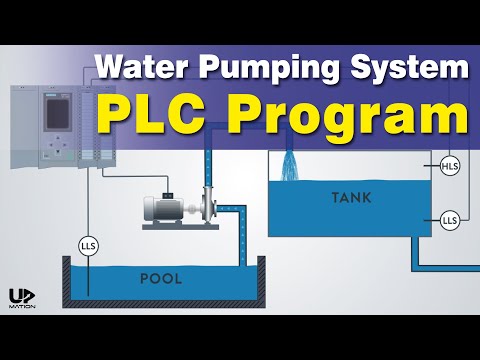

Tank Level Control with PLC ladder Logic || Animated || PLC Programming tutorials for beginners

PLC Ladder Logic Basics For Beginners With A Working Conveyor

Simple PLC Project - PLC Example with Ladder Diagram

PLC Programming Tutorials for Beginners || Ladder logic for pusher

What is Ladder Logic?

PLC Training 49 - Ladder Logic Examples | PLC Solutions

Getting Started with Programming in TwinCAT - Part 1 (LD)

Programming Siemens LOGO! 8 PLC using Ladder Diagram

Object Size detection and sorting using PLC Ladder Logic || Part #1

Basic Ladder Logic (Full Lecture)

PLC Ladder Logic Programming Examples and Solutions in - Siemens PLC Course

PLC Programming Tutorial for Beginners_ Part 1

Siemens PLC Training: How to Write PLC Ladder Program | PLC Program for Water Tank Level Control

Siemens PLC Training: Motor Start and Stop Ladder Logic PLC Program | PLC Programming Examples

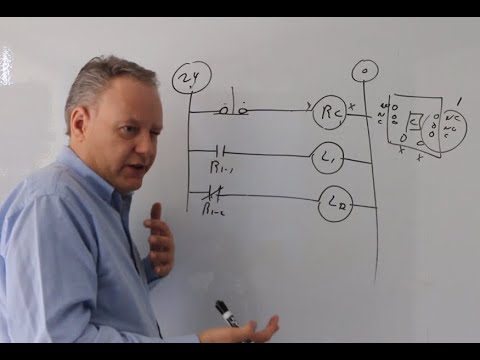

Introduction to Ladder Logic with Relays

Introduction of Ladder Programming In PLC.|| Ladder Programming Of AND,OR,NAND,NOR Gates.

#Mechatronics#PLC#Examples PLC Ladder diagram examples solutions

PLC Exercise Problems | Basic PLC Ladder Logic Examples

PLC Timer Programming for Beginners

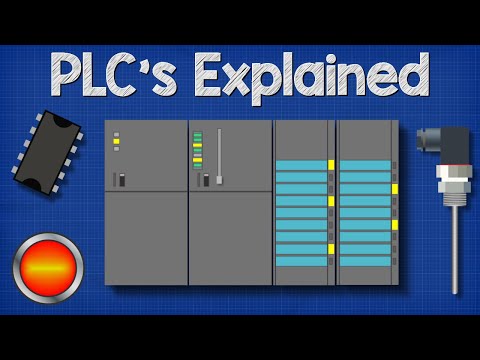

Programable Logic Controller Basics Explained - automation engineering

How to Convert a Basic Wiring Diagram to a PLC Program

Ladder Logic Best Practices: Optimizing Your PLC Programs

Комментарии

0:11:16

0:11:16

0:04:45

0:04:45

0:03:58

0:03:58

0:06:35

0:06:35

0:24:20

0:24:20

0:03:48

0:03:48

0:08:19

0:08:19

0:16:44

0:16:44

0:12:33

0:12:33

0:11:22

0:11:22

0:06:25

0:06:25

0:36:05

0:36:05

0:17:04

0:17:04

0:10:53

0:10:53

0:07:00

0:07:00

0:06:38

0:06:38

0:05:33

0:05:33

0:05:40

0:05:40

0:23:48

0:23:48

0:26:44

0:26:44

0:10:44

0:10:44

0:15:11

0:15:11

0:07:03

0:07:03

0:09:46

0:09:46