filmov

tv

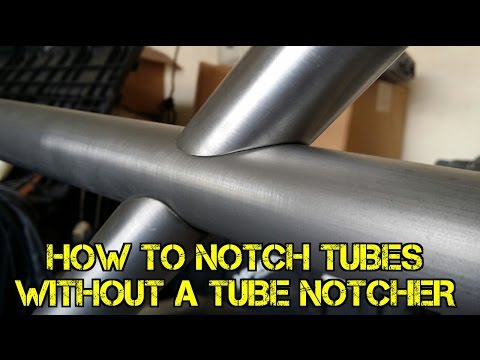

How to Notch Tubing Perfectly for Cheap! II

Показать описание

In this video I'll share another way to simply and affectively notch/cope tubing on the cheap using common garage and metal working tools. I hope you learn something from this and can apply these tips to your own projects! Thank you - Tim

WARNING, larger wheels can be dangerous...What we normally recommend is 4.5" wheels:

*This product is meant for entertainment purposes only. Your mileage may vary. Do not try this at home. Void where prohibited. Some assembly required. For off-road use only. Slippery when wet. Batteries not included. Do not use while operating a motor vehicle, heavy equipment, cherokee XJ, wrangler TJ, wrangler JK, or any Jeep vehicle, especially the newer Fiat ones. How-to videos may be too intense for some viewers and children under 30 years of age. Please remain seated until the 4x4 ride has come to a complete stop. Studies have shown viewing these videos causes increased cancer risks in laboratory test people. I am not a professional, I have no training, I'm not even particularly good at horse whispering. Don't believe everything that you know. Please keep your hands in the vehicle at all times. Do not tap on glass. Do not eat anything that has been on the floor for more than 3 days. Keep your hands to yourself. Not to be taken internally. Reproduction strictly prohibited. Driver does not carry cash. Objects in Bleepinjeep mirrors may be farther than they appear.*

09521

WARNING, larger wheels can be dangerous...What we normally recommend is 4.5" wheels:

*This product is meant for entertainment purposes only. Your mileage may vary. Do not try this at home. Void where prohibited. Some assembly required. For off-road use only. Slippery when wet. Batteries not included. Do not use while operating a motor vehicle, heavy equipment, cherokee XJ, wrangler TJ, wrangler JK, or any Jeep vehicle, especially the newer Fiat ones. How-to videos may be too intense for some viewers and children under 30 years of age. Please remain seated until the 4x4 ride has come to a complete stop. Studies have shown viewing these videos causes increased cancer risks in laboratory test people. I am not a professional, I have no training, I'm not even particularly good at horse whispering. Don't believe everything that you know. Please keep your hands in the vehicle at all times. Do not tap on glass. Do not eat anything that has been on the floor for more than 3 days. Keep your hands to yourself. Not to be taken internally. Reproduction strictly prohibited. Driver does not carry cash. Objects in Bleepinjeep mirrors may be farther than they appear.*

09521

Комментарии

0:09:58

0:09:58

0:02:24

0:02:24

0:05:02

0:05:02

0:17:06

0:17:06

0:02:53

0:02:53

0:11:39

0:11:39

0:15:01

0:15:01

0:03:20

0:03:20

0:00:47

0:00:47

0:11:35

0:11:35

0:10:45

0:10:45

0:08:46

0:08:46

0:12:05

0:12:05

0:05:29

0:05:29

0:06:24

0:06:24

0:04:32

0:04:32

0:04:05

0:04:05

0:05:43

0:05:43

0:02:54

0:02:54

0:00:59

0:00:59

0:14:53

0:14:53

0:00:58

0:00:58

0:02:28

0:02:28

0:06:10

0:06:10