filmov

tv

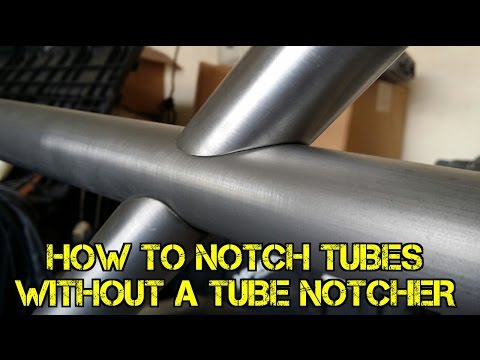

How to Notch Tube with Cheap Tools!

Показать описание

Learn to notch tubing quickly using a template and a grinder. This video shows how to create templates for quick notching and how to notch tubing if you don't have access to a tube notcher.

Tube notchers are most valuable in production work where many of the same notch are needed. In this video we discuss why an expensive tube notcher may not be worth the expense for small shops and how you can save time by just notching by hand.

0:00 Intro

1:26 Tube Notching Using a Template

5:10 Creating a Notching Template

7:03 Notching a Tube at 90 Degrees Without a Notcher

9:00 Why Tube Notchers Don't Save Much Time

13:08 Notching a Tube at 45 Degrees Without a Notcher

The Tools Featured in This Video:

As an Amazon Associate, I earn from qualifying purchases.

Empire Abrasives

Get 10% Off! Use Promo Code GarageFab

Harbor Freight Grinder

Corded 4-1/2 in. 5 Amp Angle Grinder

Welder ESAB Fabricator

Plasma Cutter Hypertherm

Vise Wilton

Hole Cutters - Hougen

Sheet Metal Shears - Kett

The Video Production Equipment I Use:

Cameras:

Sony A7iii Mirrorless Camera

Lumix G7 Mirrorless Camera

Audio Equipment:

Rode Wireless Go Lav

Giant Squid Lav

Sound Recorder Zoom H4n Pro

Tripod Manfrotto

Tripod Head

Neewer Camera Slider

Teleprompter

Lighting:

Flashpoint Ring Light

Phottix Nuada R3

Tube notchers are most valuable in production work where many of the same notch are needed. In this video we discuss why an expensive tube notcher may not be worth the expense for small shops and how you can save time by just notching by hand.

0:00 Intro

1:26 Tube Notching Using a Template

5:10 Creating a Notching Template

7:03 Notching a Tube at 90 Degrees Without a Notcher

9:00 Why Tube Notchers Don't Save Much Time

13:08 Notching a Tube at 45 Degrees Without a Notcher

The Tools Featured in This Video:

As an Amazon Associate, I earn from qualifying purchases.

Empire Abrasives

Get 10% Off! Use Promo Code GarageFab

Harbor Freight Grinder

Corded 4-1/2 in. 5 Amp Angle Grinder

Welder ESAB Fabricator

Plasma Cutter Hypertherm

Vise Wilton

Hole Cutters - Hougen

Sheet Metal Shears - Kett

The Video Production Equipment I Use:

Cameras:

Sony A7iii Mirrorless Camera

Lumix G7 Mirrorless Camera

Audio Equipment:

Rode Wireless Go Lav

Giant Squid Lav

Sound Recorder Zoom H4n Pro

Tripod Manfrotto

Tripod Head

Neewer Camera Slider

Teleprompter

Lighting:

Flashpoint Ring Light

Phottix Nuada R3

Комментарии

0:17:06

0:17:06

0:12:05

0:12:05

0:02:24

0:02:24

0:00:16

0:00:16

0:15:01

0:15:01

0:00:59

0:00:59

0:09:58

0:09:58

0:06:24

0:06:24

0:08:46

0:08:46

0:08:44

0:08:44

0:05:29

0:05:29

0:04:32

0:04:32

0:03:01

0:03:01

0:02:05

0:02:05

0:00:12

0:00:12

0:00:41

0:00:41

0:00:41

0:00:41

0:14:09

0:14:09

0:00:11

0:00:11

0:00:48

0:00:48

0:10:20

0:10:20

0:00:18

0:00:18

0:05:01

0:05:01

0:06:26

0:06:26