filmov

tv

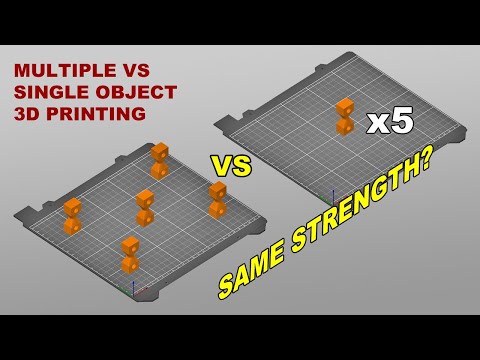

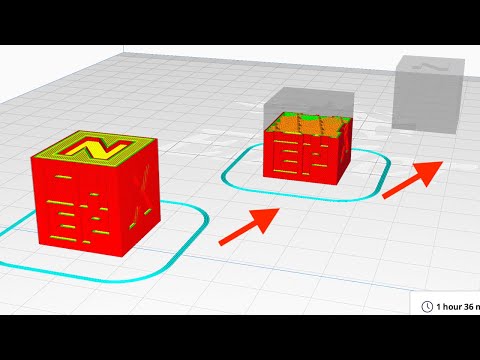

3d printing multiple objects at once vs single object 3D printing (one-by-one) - same strength?

Показать описание

I was curious, if there is any difference in strength (layer adhesion) between parts printed one at the time and those printed with other parts at the same time. Advantage of multi part 3D printing is that we have start printing only once, and printer will do the rest. There are 3 disadvantages to this method: risk, same color, stringing.

My checklist and risky factors mentioned in the video (edited according to suggestions in comment):

- small contact area

- too big overhang

- too big bridging

- tall, thin objects

- are supports added where needed

- check printing parameters

If you like my work, you could support me:

Test object used in the video can be downloaded from:

Contents:

0:00 Introduction

0:27 The theory

2:42 About layer adhesion

3:22 Preparing test specimens

4:32 Layer adhesion test

5:48 Results

5:59 Conclusions

#3dprinting

My checklist and risky factors mentioned in the video (edited according to suggestions in comment):

- small contact area

- too big overhang

- too big bridging

- tall, thin objects

- are supports added where needed

- check printing parameters

If you like my work, you could support me:

Test object used in the video can be downloaded from:

Contents:

0:00 Introduction

0:27 The theory

2:42 About layer adhesion

3:22 Preparing test specimens

4:32 Layer adhesion test

5:48 Results

5:59 Conclusions

#3dprinting

3d printing multiple objects at once vs single object 3D printing (one-by-one) - same strength?

How to 3D print multiple objects at the same time | Cookie Cutters

How to DUPLICATE & ORIENTATE your Models in CURA for 3D Printing. Mulitply a 3D Model

How to Print Multiple Models REALLY, REALLY FAST using Resin 3D Printing!

Resin VS FDM 3D printers: Which one is the best for miniatures?

How To: Maximize Batch Printing with 3D Printers

3D Printing Multiple Parts Simultaneously

5 must-know 3D printing tips & tricks. (stronger and better looking prints)

5 Best 3D Printers in 2024 | Find Your Perfect Match

10 Secret 3D Printing Tricks Only Experts Know...

One Print at a Time using Cura 4.8 Print Sequence Feature on Ender 3 V2

My Secret To No More 3D Printed Layer Lines

First Tests for any 3D Printer ⛵

Don't throw away all your 3D printing filament ends! Do this!

Fusion 360 How To Send Multiple Bodies to 3d Printer (Avoid My Mistake)

The ONE GAME-CHANGING Slicer SETTING... (Huge 3D Print Quality BOOST)

3d Printed Mechanical Counter | Best Mechanisms to 3D Print

11 USEFUL Things to 3D Print First - Practical Prints 2023

Stop 3d printing so slow!!! 🤯 (how to print faster)

Designing for multi colour/extrusion - 3D design for 3D printing

Will A 3D Printed Quarter Work In A Gumball Machine? #shorts

How much money can one 3D printer make in a week?

Stop Worrying About Settings and Build Your 3D Printer Right! #Shorts

Creality CR-30: The INFINITE 3D printer!

Комментарии

0:08:52

0:08:52

0:06:47

0:06:47

0:06:52

0:06:52

0:06:01

0:06:01

0:12:01

0:12:01

0:08:44

0:08:44

0:07:23

0:07:23

0:02:44

0:02:44

0:09:37

0:09:37

0:04:35

0:04:35

0:04:24

0:04:24

0:10:36

0:10:36

0:00:58

0:00:58

0:00:56

0:00:56

0:01:26

0:01:26

0:07:34

0:07:34

0:00:21

0:00:21

0:05:03

0:05:03

0:04:14

0:04:14

0:13:16

0:13:16

0:00:30

0:00:30

0:01:00

0:01:00

0:01:00

0:01:00

0:00:28

0:00:28