filmov

tv

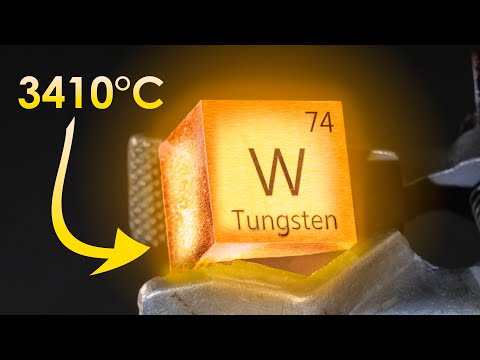

How To Melt THE MOST REFRACTORY METAL on Earth?

Показать описание

Best Patrons: Stan Presolski, reinforcedconcrete, Dean Bailey, Bob Drucker, Pradeep Sekar, Applied Science, Purple Pill, afreeflyingsoul. Thank you guys!

Today we will try to melt each of such metals and we will even attempt melting tungsten. Will we succeed at melting the most heat resistant metal on earth?

How To Melt THE MOST REFRACTORY METAL on Earth?

Can Solar Death Ray melt Tungsten and Lava Rock? #physics #experiment

Melting Strongest Metal and Diamond - Melt or Not?

How to melt chocolate (the right way) 🍫 #meltchocolate #chocolatelover

How To Melt Chocolate (Microwave and Stovetop)

Initial SETUP COST To Melt Metal At Home - FULL BREAKDOWN Of The Tools Needed

melt plastic like water

I tried to MELT chocolate with a BLOWTORCH Insane result!

'Top 10 Cutest Baby Dogs That Will Melt Your Heart!' #animalsplanetjk

Gold is ready to melt🔥💍

Why Melt is the Most Important Vocaloid Song

How To Crush And Melt Ice To Make Homemade Air 🌬

How to melt chocolate in the microwave

how to melt candy melts

How to melt chocolate using double boiler without microwave #shorts #chocolate #shortsfeed #melting

3 Easy Ways to Melt Chocolate | Allrecipes

melt Chocolates 🍫 and Butter 🧈 the RIGHT way! - Double boiler method for melting chocolates #shorts...

Acid vs Lava- Testing Liquids That Melt Everything

How to melt aluminum cans at home

USING EBIN’S MELTING SPRAY TO MELT MY LACE + HOW TO MELT LACE #WIGINSTALL | Marketa Tenay

Whats The Exact Cost Of Gas To Melt Metals- Melting Copper & Brass

How to melt chocolates Never deal with clumpy melted chocolate again.

I tried to melt candy corn again

Hot Melt Glue Gun 60W || Best Machine || Amrit Tools ||

Комментарии

0:17:29

0:17:29

0:00:59

0:00:59

0:03:04

0:03:04

0:00:23

0:00:23

0:00:23

0:00:23

0:13:20

0:13:20

0:00:11

0:00:11

0:01:00

0:01:00

0:00:57

0:00:57

0:00:15

0:00:15

0:04:56

0:04:56

0:00:10

0:00:10

0:00:19

0:00:19

0:00:15

0:00:15

0:00:16

0:00:16

0:04:30

0:04:30

0:00:15

0:00:15

0:20:37

0:20:37

0:07:16

0:07:16

0:00:46

0:00:46

0:10:15

0:10:15

0:00:35

0:00:35

0:00:53

0:00:53

0:00:12

0:00:12