filmov

tv

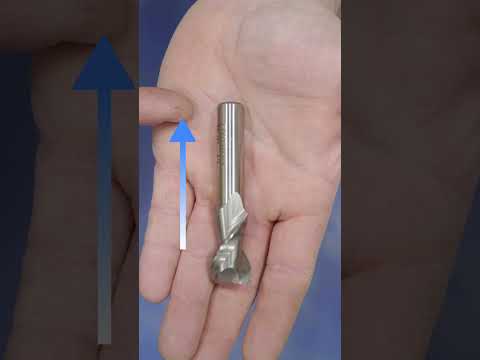

The Router Bits - How to Use Flush Trimming Bits

Показать описание

In this episode of The Router Bits, Patrick Holcombe shows us the very practical uses of Flush Trimming Bits - limited only by your creativity and imagination...

Flush trim bits are perfect for removing excess material once timber or laminates have been jointed or for duplicating the same pattern when used in conjunction with a master template across multiple work pieces.

The Best Router Bits For Beginners

99% of Beginners Don't Know the Basics of Router Bits

The Router Bits - How to Use Flush Trimming Bits

Router Bits for Beginners | Rockler Skill Builders

How To Install Router Bits

How To Use A Router | Newbie

Trimmer Router & 15 Router Bits Cutter. FULLY DETAILED Example Cuts

Watch Before Buying Your Next Router Bit | Woodworking Tips & Tricks | Router Bits |

Should a Beginner Carpenter Have THESE Tools?!

Must-Have Router Bits for Beginners

5 Router Bits for Beginner Woodworkers

When to Use Spiral vs. Straight Router Bits

Router Bits for Cutting Templates and Patterns | Rockler Skill Builder

Reviving Router Bits

Router Bit Speeds, Feed and Types

The Router Bits - Cutting Tongue and Groove

How to Use a Router | RYOBI Tools 101

Best Router Bits for Beginners

Switching Router Bits 🖐️👀

The Router Bits - How to Use Chamfer Router Bits

Freud Rabbeting Bit Set 32-502 - Variable Depth! #woodworking #freudambassador #toolreviews

Spiral Router Bits Explained

New MicroJig lock miter joint router bit has easy setup #woodworking #tools #woodshop

5 MOST USED Router Bits | Woodworking Tips

Комментарии

0:08:26

0:08:26

0:22:13

0:22:13

0:05:36

0:05:36

0:04:03

0:04:03

0:01:07

0:01:07

0:04:33

0:04:33

0:16:48

0:16:48

0:00:30

0:00:30

0:08:31

0:08:31

0:00:53

0:00:53

0:09:57

0:09:57

0:00:39

0:00:39

0:01:44

0:01:44

0:01:00

0:01:00

0:13:47

0:13:47

0:04:11

0:04:11

0:04:23

0:04:23

0:00:27

0:00:27

0:00:29

0:00:29

0:03:26

0:03:26

0:01:00

0:01:00

0:04:21

0:04:21

0:00:42

0:00:42

0:04:00

0:04:00