filmov

tv

A Noise-Free DIY Switching Power Supply - How Hard Can It Be?

Показать описание

#0:00 Welcome to element14 presents

#0:12 Overview

#1:06 Attempt 1: Breadboard

#1:47 Attempt 2: Auto Router

#4:36 Attempt 3: 6 mil Traces

#7:03 Attempt 4: 6 mil Trace ... With GND

#8:03 Attempt 5: Copper Pours FTW!

#10:03 Give your Feedback

#SMPS #powersupply #PCBdesign #SMPSdesign #PCB

A Noise-Free DIY Switching Power Supply - How Hard Can It Be?

DIY phono preamplifier part 1: low noise power supply

Design Your DIY Power Supply! (+/- 12/15V)

Free energy idea's project 🔥💡|diy project homemade|#mr_kishan_hacker #short #trending #dc

Diy electric scooter

Why hasn't Apple invented this yet?!

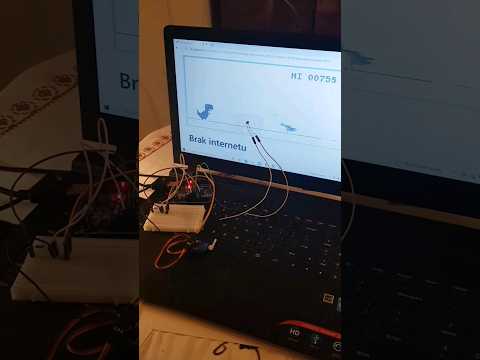

Arduino project 😎^ Arduino #arduino #2022 #2021 #2023 #dc #arduinoproject #diy #foryou

DIY Radar With Ultrasonic Sensor And Chat-GPT Generated Arduino Code | Coders Cafe

Safely Boosting Voltage: Using a 48V Voltage Booster with Batteries

DIY Powerful Ultra Bass Amplifier HDD Computer , No IC , Simple Circuit

DIY Mini Lab Bench Power Supply (With Switchable DC and AC Input)

DIY Generator😍| How to make generator step up to (400v)| #short #generator #youtubeshorts #howtomake...

DIY 4D music

30 second curbless shower #shorts #shortsvideo #diy #tile

DIY ENGINE MODEL#enginediy #enginesound #engineering #engineeringjobs #enginebuild

DIY self running 24 hour / free energy 😱 #viralshorts #trending #shorts

Eurorack DIY: Power supply interference

Shrink Tint NO Creases! #tint #cars #diy #windowtint

ARC and eARC Explained - An Awesome Feature That You're Probably Not Using (HDMI CEC)

DIY 24V 6AMP POWERFUL SMPS

DIY SMPS Power supply 12V 10A

Awesome DIY Project

DIY Peatmoss Spreader #genius #invention #peatmossspreader

Are Aftermarket Intakes Even Worth It?

Комментарии

0:10:47

0:10:47

0:09:11

0:09:11

0:21:04

0:21:04

0:00:21

0:00:21

0:00:28

0:00:28

0:01:00

0:01:00

0:00:40

0:00:40

0:00:19

0:00:19

0:10:24

0:10:24

0:11:14

0:11:14

0:11:12

0:11:12

0:00:32

0:00:32

0:00:16

0:00:16

0:00:34

0:00:34

0:00:37

0:00:37

0:00:52

0:00:52

0:05:48

0:05:48

0:00:41

0:00:41

0:07:08

0:07:08

0:08:24

0:08:24

0:18:16

0:18:16

0:01:00

0:01:00

0:00:27

0:00:27

0:10:17

0:10:17