filmov

tv

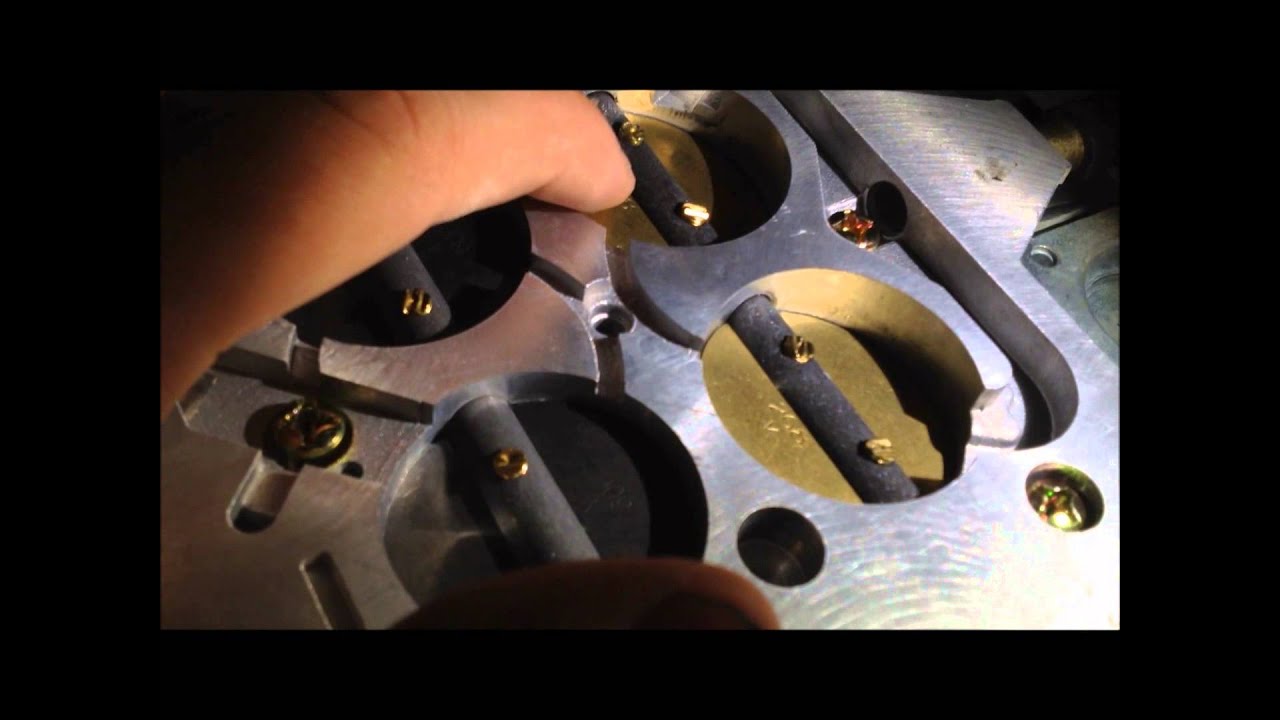

Holley Carb - Setting Idle Speed Correctly

Показать описание

the Proper method to set your idle speed on your holley carb.

How to adjust Holley Idle Mixture Screws and Curb Idle

Holley Carb - Setting Idle Speed Correctly

How To Adjust the Choke and Fast Idle on Holley Carburetors

Set & Tune Holley Carburetor Idle Mixture & Idle Speed

Holley Curb Idle speed adjustment - Tech Tip Minute

How To Set The Idle Mixture Screws On A Holley Carburetor

Adjusting Idle Mixture Screws - Holley Four Corner Adjustment

Holley Set-Up and Adjust Step By Step

Holley Carburetor - Cold Start Fast Idle Adjustment

Holley Carburetor Adjustments. I'm Not a Pro! 😂

Holley Carb Tuning Tips! | Engine Masters | MotorTrend

How To Adjust The Accelerator Pump Arm on a Holley Carburetor

The Holley Carb Adjustment That Has A Twist - A Seemingly Simple Variation With A Big Difference

Holley Carburetor Tuning: Idle Circuit Mods for High Duration Camshafts

SETTING UP AND TUNING HOLLEY IDLE AND TRANSITION CICUITS | Holley Carb Secrets |How To Tune A Holley

How to Adjust a Carburetor 4-Corner Idle System

MOST COMMON Misadjusted Holley Carburetor Setting (2 second Fix)

How to Tune Idle on 2 Barrel Holley

Holley Carb: Setting Idle Setting & Initial Ignition Timing (CARB BASICS PART:1)

Holley Idle Mixture Adjustment - Tech Tip Minute

4 corner idle mixture tuning on your Holley carb. Vacuum gauge vs dual wideband.

Holley Carb Rich/Lean Adjustment

HOW TO SET HOLLEY IDLE MIXTURE AND IDLE SPEED | Holley Carb Secrets | Holley Carburetor

Understanding Your Holley Idle Circuit

Комментарии

0:09:17

0:09:17

0:08:01

0:08:01

0:03:06

0:03:06

0:04:52

0:04:52

0:01:00

0:01:00

0:04:56

0:04:56

0:05:48

0:05:48

0:11:54

0:11:54

0:03:46

0:03:46

0:01:00

0:01:00

0:03:24

0:03:24

0:03:37

0:03:37

0:08:16

0:08:16

0:12:02

0:12:02

0:10:59

0:10:59

0:01:21

0:01:21

0:07:52

0:07:52

0:03:50

0:03:50

0:13:05

0:13:05

0:01:12

0:01:12

0:04:48

0:04:48

0:03:20

0:03:20

0:15:58

0:15:58

0:08:00

0:08:00