filmov

tv

🔥Pipe Roots: Short Circuit MIG (Roll Out)

Показать описание

🔥NEW VIDEOS EVERY MONDAY AND FRIDAY 🔥

Today we're talking about rolling out pipe using the short circuit MIG process. This is done heavily in the pre-fabrication on pipe.

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

EQUIPMENT WE USE:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

► ESAB Power Sources: www.ESAB.com

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

JOIN US ON:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Today we're talking about rolling out pipe using the short circuit MIG process. This is done heavily in the pre-fabrication on pipe.

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

EQUIPMENT WE USE:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

► ESAB Power Sources: www.ESAB.com

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

JOIN US ON:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

🔥Pipe Roots: Short Circuit MIG (Roll Out)

Walking The Cup on MIG Welding | Modified Short Circuit Root Pass

Short Circuit Mig Fillet Welds and more...

3G MIG Uphill Pulse Spray vs Short Circuit

Short Circuit MIG Pipe Roll Out | TIG Time

Subarc hot pass over short circuit mig root

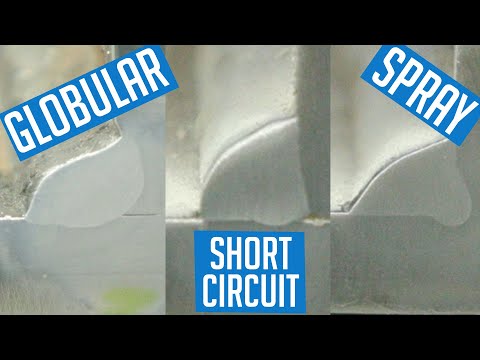

Welding Modes | Short Circuit vs Spray vs Globular

MIG Welding Basics: What is Short Circuit Transfer?

5G Pipe MIG Welding | Welding Tips & Tricks #Welding #MIG #WeldingTips

Mig Welding Pipe Roots, & Other Stuff

MIG Weld Open Root in Roll-Out !

MIG Welding 3g Vertical Open Root Plate Test

MIG Welding a Butt Joint: Techniques and Tips (1G/PA)!

3F 2 Pass Vertical MIG Weld

Uncovering the Shocking Science Behind Short Circuit MIG Welding

Mig root👨🏭👩🏿🏭 #pipewelder #welder

PrimeWeld MIG 180 Wire Speed Settings

MIG Welding 3g Plate Uphill Root vs Downhill

Beginners Guide to SHORT CIRCUIT MIG WELDING

MIG Welding Open Root Pipe

Setting Wire Speed On A Mig Welder To Match Voltage, Must See For Beginners Learning Welding

How NOT TO Weld: Most Common MIG Welding Mistakes

Short Circuit MIG Stainless Bend Test

Dual Shield Flux Core and Short Circuit MIG Welding

Комментарии

0:06:52

0:06:52

0:04:23

0:04:23

0:10:21

0:10:21

0:06:29

0:06:29

0:15:26

0:15:26

0:00:34

0:00:34

0:09:35

0:09:35

0:01:03

0:01:03

0:09:08

0:09:08

0:06:59

0:06:59

0:03:01

0:03:01

0:06:05

0:06:05

0:01:43

0:01:43

0:03:16

0:03:16

0:00:55

0:00:55

0:01:01

0:01:01

0:06:54

0:06:54

0:06:29

0:06:29

0:23:16

0:23:16

0:10:01

0:10:01

0:06:40

0:06:40

0:16:44

0:16:44

0:13:16

0:13:16

0:08:40

0:08:40