filmov

tv

Adjusting the Valve Lash on our Cummins 6.7 Diesel Engine

Показать описание

** Something I forgot to mention in the video - Always adjust your engines valves COLD. This engine was at ambient temp about 75 degrees F.

Also, In the video it appears at times the feeler gauges are bending. Like at 5:43 You cannot check proper tolerance with a bent gauge. Later I removed the gauge from the pack and put a bend in it so that it slid in without any resistance. Should have put this in the video because its critical.

Below is the procedure for the 6.7 Engine (2010) from the service manual.

*******************

Overhead setting is only required at the interval specified in the appropriate Operation and Maintenance Manual/Owners Manual or when engine repairs cause removal of the rocker levers and/or loosening of the adjusting screws.

Excessive valve lash prior to this can indicate an overhead set incorrectly from a previous repair, worn valve stems, crossheads, push rods, or rocker levers*.

Loose rocker levers and the need to reset the valve clearance frequently can also indicate camshaft lobe or tappet wear. If an inspection of the rocker levers, valve stems, crossheads, and push rod does not show wear, then tappet and/or camshaft lobe wear can be suspected.

NOTE: The TDC indicator is on the vibration damper/crankshaft speed indicator ring.

For 6.7 L engines, align the vibration damper/crankshaft speed indicator ring so that the TDC indicator is at the 12-o'clock position. If both number 1 cylinder rocker levers are loose, move to the following steps. If both number 1 cylinder rocker levers are not loose, rotate the crankshaft 360 degrees.

With the engine in this position, lash can be measured on the following rocker levers:

(E = exhaust, I = Intake)

1I, 1E, 2I, 3E, 4I, and 5E.

Lash Check Limits

mm in Intake 0.152 MIN 0.006 0.381 MAX 0.015 Exhaust 0.381 MIN 0.015 0.762 MAX 0.030

NOTE: Checking the overhead setting is usually performed as part of a troubleshooting procedure, and resetting is not required during checks as long as the lash measurements are within the above ranges.

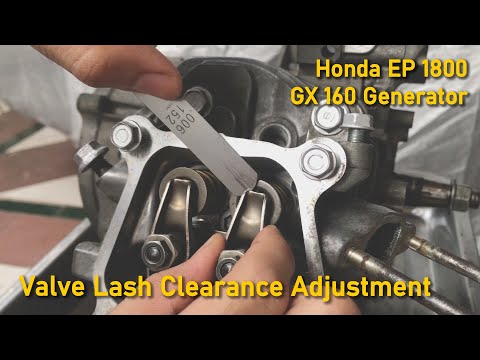

NOTE: The clearance is correct when some resistance is “felt” when the feeler gauge is slipped between the crosshead and the rocker lever socket.

Measure lash by inserting a feeler gauge between the crosshead and the rocker lever socket. If the lash measurement is out of specification, loosen the locknut, and adjust the lash to nominal specifications.

Valve Lash Specifications (Nominal)

mm in

Intake 0.254 0.010

Exhaust 0.508 0.020

Tighten the locknut and measure the lash again.

Torque Value:

24 n.m

[212 in- lb ]

Using barring tool, Part Number 3824591 (I used A 15mm ratchet on the vibration damper nut) , rotate the crankshaft 360 degrees.

Following the same steps and specifications as previously stated, measure lash for the following rocker levers:

(E = exhaust, I = Intake)

Six-cylinder 2E, 3I, 4E, 5I, 6I, and 6E.

Reset if out of specification.

******************************************

I hope this is useful information to someone. Feel free to let me know if you have any questions on how we did this.

TAGS #TRUCK #CUMMINS #6.7 #DODGE #DIESEL #VALAVE LASH #DURAMAX #POWERSTROKE #HOW TO #MORTONSONTHEMOVE

Комментарии

0:06:29

0:06:29

0:04:50

0:04:50

0:02:49

0:02:49

0:05:21

0:05:21

0:05:48

0:05:48

0:06:04

0:06:04

0:04:26

0:04:26

0:09:38

0:09:38

0:11:49

0:11:49

0:07:58

0:07:58

0:11:52

0:11:52

0:12:21

0:12:21

0:03:43

0:03:43

0:09:53

0:09:53

0:02:12

0:02:12

0:06:59

0:06:59

0:22:20

0:22:20

0:04:40

0:04:40

0:03:10

0:03:10

0:13:55

0:13:55

0:01:33

0:01:33

0:00:16

0:00:16

0:05:14

0:05:14

0:04:57

0:04:57