filmov

tv

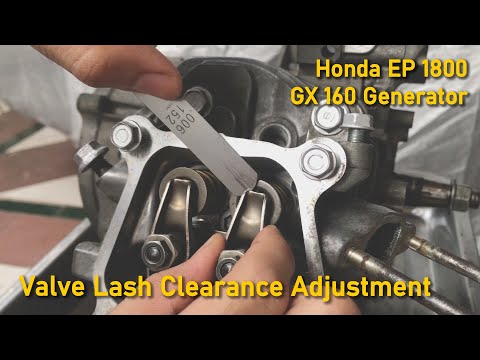

Small Engine Repair Valve Lash Clearance Adjustment on Honda, Predator, or any Engine

Показать описание

With that loud of an engine knock it was a long shot to just reset the valve lash clearance. If you watch to the end you will see the engine knocking is coming from the connecting rod on the shaft. Since nobody reads this description I’ll probably get a lot of people saying they knew right off hand that it was the connecting rod. This video isn’t to all those small engine experts. Its for those fix it in your garage type that want to add something to their bag of tricks.

Keep in mind, do this when the engine is cold.

This system works for all small engines. Doesn’t matter if you have a Honda, Briggs, Tecumseh, or even everyone’s favorite the Harbor Freight Predator 212. If you remove the pull cord assembly and it doesn’t have a triangle to designate TDC, top dead center (or both valves fully closed), you can pull the spark plug and put a screwdriver in and see when the piston is at TDC, then continue.

Here are some other links to more small engine repair videos:

Keep in mind, do this when the engine is cold.

This system works for all small engines. Doesn’t matter if you have a Honda, Briggs, Tecumseh, or even everyone’s favorite the Harbor Freight Predator 212. If you remove the pull cord assembly and it doesn’t have a triangle to designate TDC, top dead center (or both valves fully closed), you can pull the spark plug and put a screwdriver in and see when the piston is at TDC, then continue.

Here are some other links to more small engine repair videos:

Комментарии

0:05:21

0:05:21

0:05:14

0:05:14

0:04:40

0:04:40

0:04:17

0:04:17

0:10:55

0:10:55

0:17:03

0:17:03

0:07:39

0:07:39

0:08:20

0:08:20

3:25:40

3:25:40

0:04:57

0:04:57

0:11:48

0:11:48

0:04:39

0:04:39

0:07:37

0:07:37

0:03:18

0:03:18

0:04:33

0:04:33

0:02:51

0:02:51

0:12:50

0:12:50

0:04:52

0:04:52

0:09:59

0:09:59

0:16:15

0:16:15

0:03:56

0:03:56

0:08:22

0:08:22

0:10:46

0:10:46

0:06:32

0:06:32