filmov

tv

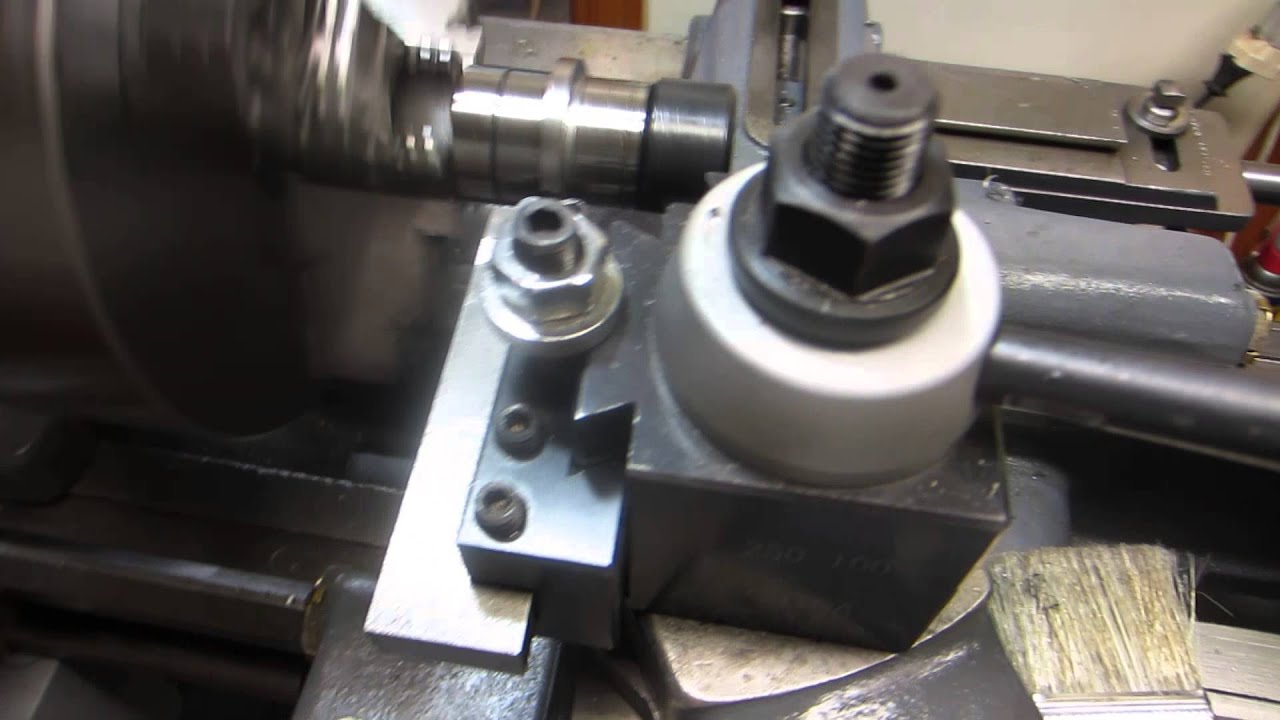

Making an involute gear cutter: Part 1 - Forming the profile

Показать описание

First attempt at making a home shop made involute gear cutter. I followed the process as detailed in Ivan Law's book, Gears and Gear Cutting, but I followed the formulas as published by John Stevenson as there are apparently some discrepancies in the formulas used in Law's tables. I'm not sure YouTube will let me publish links, but I'll try to nevertheless. Also a quick Thank You to YouTube users myfordboy and mrpete222, whose videos have inspired me to try this leap-of-faith dive into the far deep end of the machining pool.

Forming An 'Involute' Gear Profile With Button Cutters

Making An 'Involute' Profile Fly Cutter

Tools, Glorious Tools! #10 (Part 3) - Shop Made Gear Cutters - Making 'Involute' Gear Cutt...

Making an involute gear cutter: Part 1 - Forming the profile

Heat Treating & Sharpening A Shop Made Gear Cutter

Forming Gear Cutter Faces On The Mill

Cutting A 30 Tooth 'Involute' Gear In Brass

Making A Rack Involute System Fly Cutter

Spline making with Involute Gear Cutters

Cutting a 30 Tooth 'Involute' Gear In Mild Steel, Using a Shop Made Cutter.

Making A Gear Cutter Blank

Gears! - But Were Afraid To Ask (MiniLathe)

Tools, Glorious Tools! #10 (Part 2) - Shop Made Gear Cutters - The Cutter Forming Tools

Cutting Gear Teeth On The Lathe

Internal Gear cutting of 650mm diameter, planetary ring gear at WA Gears #engineering #gearcutting

Making Gears From Scratch

Shaper Machine - Involute Gear Cutting

Making gear cutters in the home workshop using Eureka tool

Select a cutter for making gears

How to Choose a Milling Gear Cutter & Buy One - Milling a Gear 3

how to make an involute gear by hobbing process

Involuter? I barely know her!

Making gears without the need for a gear cutter

Making A 'Cycloidal' Gear Tooth Fly Cutter

Комментарии

0:03:18

0:03:18

0:03:19

0:03:19

0:31:18

0:31:18

0:11:49

0:11:49

0:03:24

0:03:24

0:02:37

0:02:37

0:02:21

0:02:21

0:03:13

0:03:13

0:11:54

0:11:54

0:03:01

0:03:01

0:03:44

0:03:44

0:29:02

0:29:02

0:23:05

0:23:05

0:02:54

0:02:54

0:00:30

0:00:30

0:12:26

0:12:26

0:17:27

0:17:27

0:17:37

0:17:37

0:13:15

0:13:15

0:10:15

0:10:15

0:02:41

0:02:41

0:23:35

0:23:35

0:03:55

0:03:55

0:02:55

0:02:55