filmov

tv

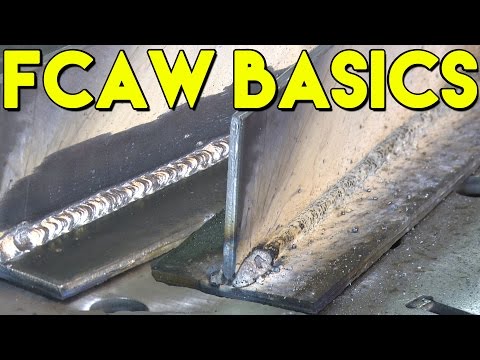

“Gasless” MIG Welding Explained!

Показать описание

In this video I show you a quick difference between a mig weld, and a flux core weld. I get tons of messages on instagram asking for advice on buying a first welder. Lots of people opt to save money up front and go "gasless" but that can leave you stuck when it comes time to take your work to the next level!

For links to what I used in this video, see below, as an amazon affiliate I earn from qualifying purchases:

The welder I used in this video:

Lincoln 140MP

Siegmund Welding Table:

Milwaukee Variable Speed Angle Grinder

Pferd Flap Disc

1-2-3 Blocks, use them for welding an upset machinists everywhere.

Check out the Lincoln Electric Power Mig 140MP, great for the home shop, Mig, TIG, and Stick in 1 machine!

Thank you to Pferd abrasives for supporting my shop and my channel. For links to some of the grinding discs I use most see below:

As an Amazon Associate I earn from qualifying purchases.

→ Flap disc:

→ Inside corner disc (AMAZING):

→ Wire Wheel:

Thanks for watching! Be careful, know the limits of your skills and your tools! Don't try this stuff at home!

Like and Subscribe for more videos and check out our Instagram

To help support Make Everything and this channel become a Patron:

For Make Everything T-shirts, hats and other products check out our website:

For PDFs of some of our project check out our profile on Instructables:

Below are some links to tools I use in the shop on a daily basis.

Starbond CA Glue:

As an Amazon Associate I earn from qualifying purchases.

→ Bosch Miter Saw ( My Favorite miter saw)

→ Sawstop Table Saw:

→ Wen Tabletop Metalcutting Bandsaw

→ Articulated Vise:

→ Bosch Portable Bandsaw ( 18V)

→ Porter Cable Restorer:

→ Lincoln 120V Welder ( good for a home shop)

→ The Camera I use:

→ The Tripod I use:

For links to what I used in this video, see below, as an amazon affiliate I earn from qualifying purchases:

The welder I used in this video:

Lincoln 140MP

Siegmund Welding Table:

Milwaukee Variable Speed Angle Grinder

Pferd Flap Disc

1-2-3 Blocks, use them for welding an upset machinists everywhere.

Check out the Lincoln Electric Power Mig 140MP, great for the home shop, Mig, TIG, and Stick in 1 machine!

Thank you to Pferd abrasives for supporting my shop and my channel. For links to some of the grinding discs I use most see below:

As an Amazon Associate I earn from qualifying purchases.

→ Flap disc:

→ Inside corner disc (AMAZING):

→ Wire Wheel:

Thanks for watching! Be careful, know the limits of your skills and your tools! Don't try this stuff at home!

Like and Subscribe for more videos and check out our Instagram

To help support Make Everything and this channel become a Patron:

For Make Everything T-shirts, hats and other products check out our website:

For PDFs of some of our project check out our profile on Instructables:

Below are some links to tools I use in the shop on a daily basis.

Starbond CA Glue:

As an Amazon Associate I earn from qualifying purchases.

→ Bosch Miter Saw ( My Favorite miter saw)

→ Sawstop Table Saw:

→ Wen Tabletop Metalcutting Bandsaw

→ Articulated Vise:

→ Bosch Portable Bandsaw ( 18V)

→ Porter Cable Restorer:

→ Lincoln 120V Welder ( good for a home shop)

→ The Camera I use:

→ The Tripod I use:

Комментарии

0:12:45

0:12:45

0:15:50

0:15:50

0:11:36

0:11:36

0:18:42

0:18:42

0:09:34

0:09:34

0:03:05

0:03:05

0:03:53

0:03:53

0:11:50

0:11:50

0:11:27

0:11:27

0:04:16

0:04:16

0:12:10

0:12:10

0:14:40

0:14:40

0:06:50

0:06:50

0:07:44

0:07:44

0:05:03

0:05:03

0:02:56

0:02:56

0:09:46

0:09:46

0:22:14

0:22:14

0:05:00

0:05:00

0:07:17

0:07:17

0:08:29

0:08:29

0:06:42

0:06:42

0:16:44

0:16:44

0:08:08

0:08:08