filmov

tv

How to Design Parts for CNC Machining

Показать описание

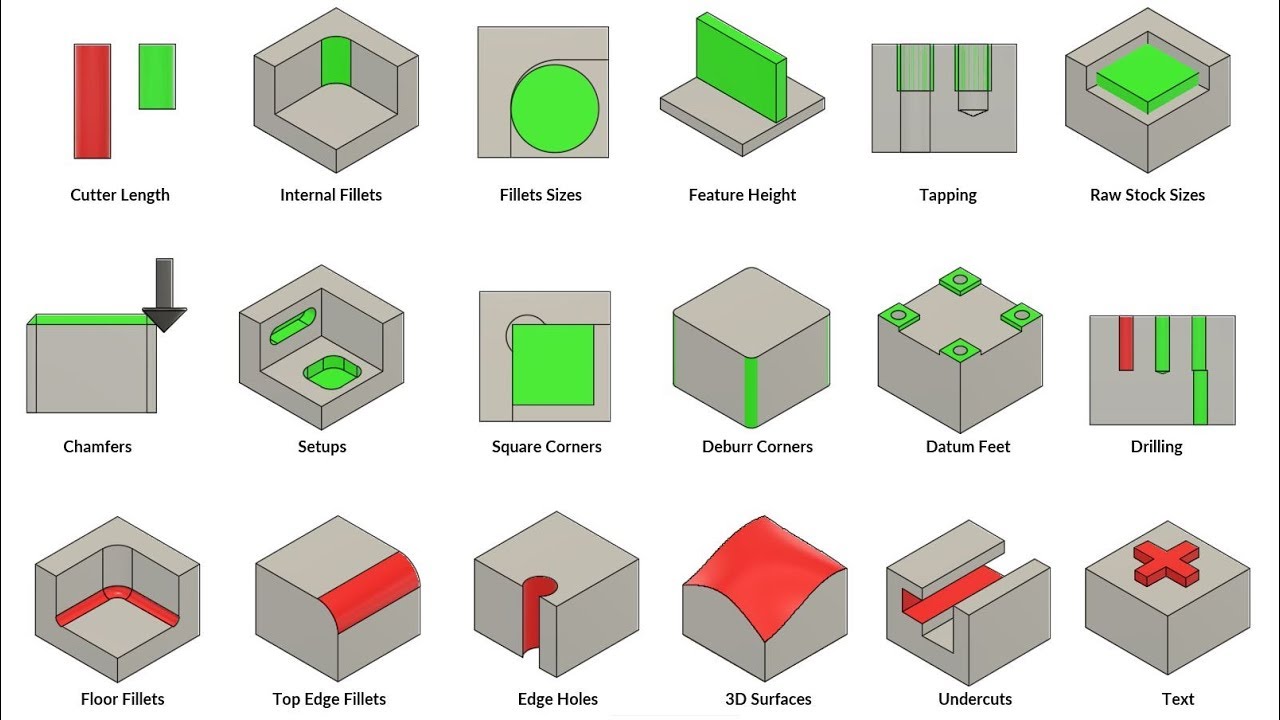

I this video, I will go over some of the top tips and tricks on how you can improve your designs and decrease cost while optimizing for manufacturing on a CNC milling process.

I’ll cover everything from fillets, chamfers, setups, drilling, tapping, undercuts and even text. Shortcut links are for everything below. Full article posted on my website below.

00:28 - CNC Milling Machine

01:06 - Common Cutting Tools

01:52 - End Mill Deflection

02:39 - Internal Fillets

03:05 - Fillet Specifics

03:37 - Dogbone Corners

03:45 - Feature Height

04:00 - Threads and Tapping

04:36 - Raw Stock Size

05:01 - Chamfers

05:31 - Setups

06:07 - External Fillets

06:28 - Isolate Tight Tolerance Areas

06:47 - Drilling

07:15 - Bottom Floor Fillets

07:38 - Edge Break Fillets

07:56 - Edge Drilling

08:21 - 3D Surfacing

08:41 - Undercuts

08:58 - Text

09:18 - Bad Example Part

09:47 - Fixing a Bad Part

10:09 - Price Comparison of Good and Bad Part

10:19 - Good Books for Going Further

10:33 - More Links for Learning

Good Books (Affiliate links, your help supports the channel):

CNC Online Quoting:

Finding Material:

Machining Videos:

I’ll cover everything from fillets, chamfers, setups, drilling, tapping, undercuts and even text. Shortcut links are for everything below. Full article posted on my website below.

00:28 - CNC Milling Machine

01:06 - Common Cutting Tools

01:52 - End Mill Deflection

02:39 - Internal Fillets

03:05 - Fillet Specifics

03:37 - Dogbone Corners

03:45 - Feature Height

04:00 - Threads and Tapping

04:36 - Raw Stock Size

05:01 - Chamfers

05:31 - Setups

06:07 - External Fillets

06:28 - Isolate Tight Tolerance Areas

06:47 - Drilling

07:15 - Bottom Floor Fillets

07:38 - Edge Break Fillets

07:56 - Edge Drilling

08:21 - 3D Surfacing

08:41 - Undercuts

08:58 - Text

09:18 - Bad Example Part

09:47 - Fixing a Bad Part

10:09 - Price Comparison of Good and Bad Part

10:19 - Good Books for Going Further

10:33 - More Links for Learning

Good Books (Affiliate links, your help supports the channel):

CNC Online Quoting:

Finding Material:

Machining Videos:

Комментарии

0:10:58

0:10:58

0:09:51

0:09:51

0:15:40

0:15:40

0:04:56

0:04:56

0:00:13

0:00:13

0:11:09

0:11:09

0:00:20

0:00:20

0:01:53

0:01:53

0:00:17

0:00:17

0:16:21

0:16:21

0:17:44

0:17:44

0:00:34

0:00:34

0:07:51

0:07:51

0:05:54

0:05:54

0:00:51

0:00:51

0:05:28

0:05:28

0:01:01

0:01:01

0:04:31

0:04:31

0:01:01

0:01:01

0:17:54

0:17:54

0:02:23

0:02:23

0:05:36

0:05:36

0:12:06

0:12:06

0:11:12

0:11:12