filmov

tv

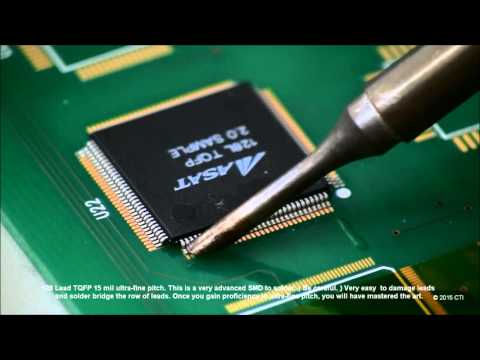

Soldering MCU & QFN IC Chips with Hot Air Station

Показать описание

This video will show you how to reflow solder a QFN chip.

We will remove, inspect, and replace an MCU (microcontroller) using a hot rework station.

The hot air station is 1000 watts, and the flux used is ChipQuik NoClean 30cc Syringe.

Hot air temperature setting is 385C and 36 air speed.

Here are links to the tools used in this video:

Please help out the channel by using the affiliate links above.

Please leave comments down below!

We will remove, inspect, and replace an MCU (microcontroller) using a hot rework station.

The hot air station is 1000 watts, and the flux used is ChipQuik NoClean 30cc Syringe.

Hot air temperature setting is 385C and 36 air speed.

Here are links to the tools used in this video:

Please help out the channel by using the affiliate links above.

Please leave comments down below!

Soldering MCU & QFN IC Chips with Hot Air Station

How To Solder SMD / Surface Mount IC ( QFN , QFP + PLCC )

How to Solder QFN MLF Package by Hand (Using a Hot Air Rework Station) | Digi-Key Electronics

How to Soldering QFN (Quad Flat No-Lead) IC's Full Details in Hindi (#006) #Electrobias

how to desolder smd QFN IC

Master Soldering: Surface Mount Fine-Pitch - Highly Recommended

Micro Soldering Techniques Episode 01 - How To Solder A QFN IC (Step By Step Video Tutorial)

QFN Soldering - How To Replace QFN / How To Rework QFN

How to solder 0.5mm pitch LQFP 144 pin IC

Replacing and Soldering QFN Chips - Mitch's Microsoldering Tips #2

Easiest way to solder QFN package IC

How to Solder a QFN chip (AD7779)

MCU HC08 soldering

removing and soldering a large smd qfp64 ic with quick station hot air rework

Drag soldering a 100 pin 14mm QFP for a PiStorm 600

28pin QFN SMD IC De-Soldering Tips & Tricks.

SMD SOLDERING - QFN IC PLACEMENT PART 5 #shorts #shortsfeed #shortsvideo #youtubeshorts #smd

Dead Micro Chip SMD swap | Resolder #shorts #microsoldering #smdsoldering #fpvrepair #bandifpv #asmr

A good hot air station from @phonefix Hot Air Gun Rework Station

QFN-28 Soldering Trials and Tribulations

Desoldering & Soldering ic chip #ic #icchip #electronic #short

SOLDERING SMD IC QFN PACKAGE

SOLDERING QFN IC USING SOLDER PASTE (me learning to solder)

QFN Package 😘 #soldering #repair #electronic

Комментарии

0:08:34

0:08:34

0:38:45

0:38:45

0:13:29

0:13:29

0:09:45

0:09:45

0:00:48

0:00:48

0:04:00

0:04:00

0:27:56

0:27:56

0:07:58

0:07:58

0:06:20

0:06:20

0:26:33

0:26:33

0:09:31

0:09:31

0:05:50

0:05:50

0:00:16

0:00:16

0:02:55

0:02:55

0:03:08

0:03:08

0:02:46

0:02:46

0:00:17

0:00:17

0:01:00

0:01:00

0:00:26

0:00:26

0:06:54

0:06:54

0:00:19

0:00:19

0:00:44

0:00:44

0:07:30

0:07:30

0:00:30

0:00:30