filmov

tv

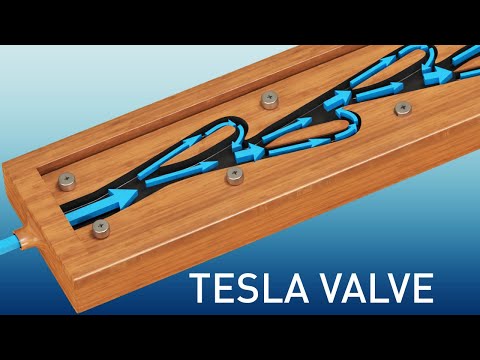

3d Tesla Valve Simulation Way More efficient!!

Показать описание

We will be installing this on our new pulse-jet soon attached to dual stage metal Tesla Turbine. This is just the beginning of our new pulse jet testing to power the turbine. We found out the 3d design was way more efficient.

Thank to

Blain, Alessio and Robert for helping with the design and simulation.

Thank to

Blain, Alessio and Robert for helping with the design and simulation.

3d Tesla Valve Simulation Way More efficient!!

This Tesla Valve Straw Only Works In One Direction

Tesla valve in action

TESLA VALVE (FLUID SIMULATION) #Shorts

Tesla Valve | The complete physics

Tesla Valve

IT WORKS!! 3D Tesla Valve Simulation

The Tesla Valve

Large scale Tesla valve (1 meter) with dye

3D MODEL OF TESLA VALVE

3D TESLA VALVE

Inside a Tesla Valve - Fluid Dynamics

Tesla Valve OpenFOAM: Large Eddy Simulation

TESLA VALVE Flow Simulation in SOLIDWORKS | Solidworks simulation tutorial for beginners.

3D render of a Tesla valve

Modular Vortex Tesla Valve - Concept

Can a Tesla Valve stop a MEGA TSUNAMI in Cities Skylines?

Nicolas Tesla's One-Way-Valve (Exciting Physical Phenomena) ∇ OpenFOAM®

Tesla Valve flow simulation using Open Foam

Real experiment shows how Tesla valve works

How to do an analysis on Tesla Valve in Ansys Fluent

Drinking Through a Tesla Valve Straw

TESLA Valve design and Fluid velocity and pressure Testing | Solidworks flow simulation for beginner

#Tesla Valve #Flow #Simulation using #Ansys #Discovery Live

Комментарии

0:01:46

0:01:46

0:08:58

0:08:58

0:00:23

0:00:23

0:00:42

0:00:42

0:06:02

0:06:02

0:00:11

0:00:11

0:08:35

0:08:35

0:00:44

0:00:44

0:00:29

0:00:29

0:03:00

0:03:00

0:01:32

0:01:32

0:02:37

0:02:37

0:01:56

0:01:56

0:13:12

0:13:12

0:05:29

0:05:29

0:02:19

0:02:19

0:19:48

0:19:48

0:00:35

0:00:35

0:05:50

0:05:50

0:00:52

0:00:52

0:09:52

0:09:52

0:00:58

0:00:58

0:13:50

0:13:50

0:03:25

0:03:25