filmov

tv

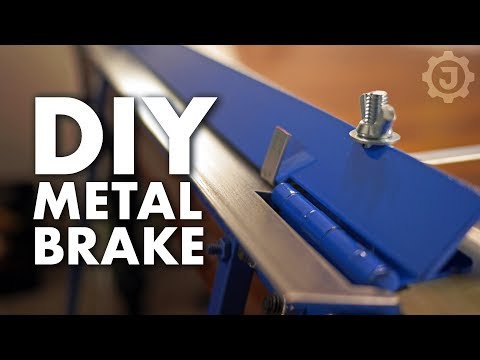

DIY sheet metal bending brake for under $30

Показать описание

This is how I built a simple bending brake with just a skill saw, drill and some hand tools. It works great!

#bendingbrake

#diymachinery

#bendingbrake

#diymachinery

How to make a DIY sheet metal brake | I Like To Make Stuff

Adam Savage's Favorite Tools: Handheld Sheet Metal Brake

DIY Sheet Metal Bending Brake: No Welding

Ironton 30' Sheet Metal Bending Brake from Northern Tool + Equipment. Full Review!

How to make sheet metal bending machine

DIY sheet metal bending brake for under $30

Best 30' Metal Brake Modification! (Easy To Do!)

GOOD DIY SHEET METAL BRAKE

Multi-shape Bending by BM Press Brake. #machine

My new favorite CHEAP Harbor Freight tool!

TOP 7 YOUTUBE METAL BENDER IDEAS!!!

How to Make a Homemade Sheet Metal Brake

Multiple Bends with the Metal Bender by Malco

KAKA Industrial 4 in hand Operated Steel Bending Brake, Sheet Metal Forming Bender FB-4

CNC Press Brake Machine, Sheet Metal Bending Machine for bending box cabinet China AMADA Machine

Pan and Box Brake Magnabend Magnetic sheet metal brake Bending Machines Sheet metal press brake

How To Make a DIY Sheet Metal Brake *CHEAP*

KAKA Industrial EB4816B Manual Magnetic Sheet Metal Box and Pan Brake, 1-Phase 220V

✔️ DIY No Weld Sheet Metal Brake

How To Bend Sheet Metal Without A Brake

DIY Metal Brake for Bending Sheet Metal

DIY sheet metal bending jig

Making an Inset Bench Metal Folder/Brake

Edge Roller Bender on a Budget, DIY Steel Roofing Roller

Комментарии

0:07:07

0:07:07

0:02:58

0:02:58

0:07:30

0:07:30

0:07:50

0:07:50

0:09:26

0:09:26

0:07:14

0:07:14

0:16:14

0:16:14

0:18:45

0:18:45

0:00:15

0:00:15

0:06:55

0:06:55

0:15:46

0:15:46

0:06:10

0:06:10

0:00:47

0:00:47

0:00:59

0:00:59

0:00:49

0:00:49

0:00:09

0:00:09

0:12:03

0:12:03

0:01:35

0:01:35

0:08:38

0:08:38

0:06:04

0:06:04

0:12:14

0:12:14

0:02:20

0:02:20

0:12:43

0:12:43

0:17:10

0:17:10