filmov

tv

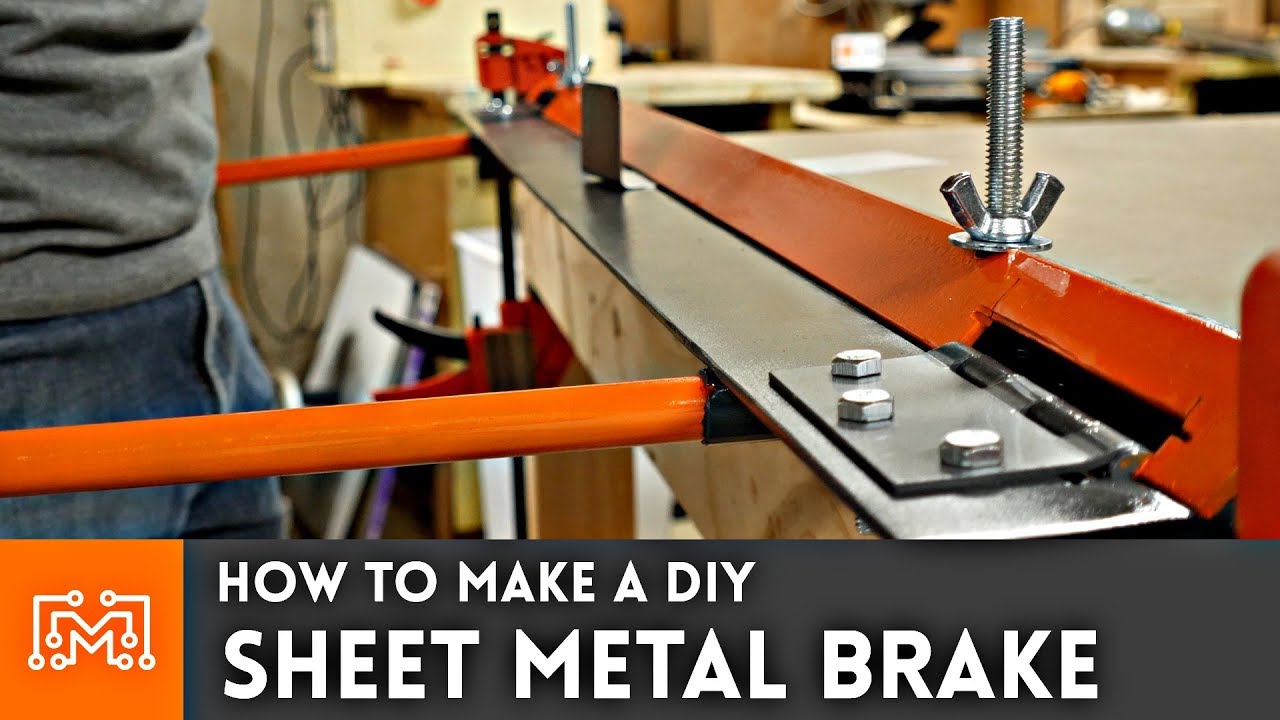

How to make a DIY sheet metal brake | I Like To Make Stuff

Показать описание

Need to bend sheet metal? It's really easy to build a simple DIY metal brake!!

TOOLS & SUPPLIES:

A FEW OTHER METAL BRAKE PROJECTS:

(There are LOTS out there)

A few weeks back, I was working on a project that required bending some thin sheet metal and was having some trouble. While on a Google hangout with my Patreon supporters, my friend Evan mentioned making a sheet metal brake. I started looking into it and found lots of DIY versions online. There were all different types requiring different tools and providing different results. I mashed up techniques from several of them and made one in an afternoon!This is a 4 ft version that clamps down to an existing table when in use. When I'm finished with it, I can easily hide it away in seconds. This is great for folding aluminum, steel and more. There are lots of different ways to make these tools, some of which don't even require welding! Check it out!

Learn 3d modeling, get digital plans, and cool merch at

Want to support ILTMS? Get exclusive content and more...

FOLLOW:

#ILikeToMakeStuff

About I Like To Make Stuff:

We have lots of projects including woodworking, metalworking, electronics, 3D printing, prop making and more!

These videos are our attempt inspire and empower others to make the stuff that they want to have. Hopefully you'll see something here that will inspire you to make something that you're passionate about!

How to make a DIY sheet metal brake | I Like To Make Stuff

I Like To Make Stuff

TOOLS & SUPPLIES:

A FEW OTHER METAL BRAKE PROJECTS:

(There are LOTS out there)

A few weeks back, I was working on a project that required bending some thin sheet metal and was having some trouble. While on a Google hangout with my Patreon supporters, my friend Evan mentioned making a sheet metal brake. I started looking into it and found lots of DIY versions online. There were all different types requiring different tools and providing different results. I mashed up techniques from several of them and made one in an afternoon!This is a 4 ft version that clamps down to an existing table when in use. When I'm finished with it, I can easily hide it away in seconds. This is great for folding aluminum, steel and more. There are lots of different ways to make these tools, some of which don't even require welding! Check it out!

Learn 3d modeling, get digital plans, and cool merch at

Want to support ILTMS? Get exclusive content and more...

FOLLOW:

#ILikeToMakeStuff

About I Like To Make Stuff:

We have lots of projects including woodworking, metalworking, electronics, 3D printing, prop making and more!

These videos are our attempt inspire and empower others to make the stuff that they want to have. Hopefully you'll see something here that will inspire you to make something that you're passionate about!

How to make a DIY sheet metal brake | I Like To Make Stuff

I Like To Make Stuff

Комментарии

0:00:23

0:00:23

0:00:16

0:00:16

0:00:16

0:00:16

0:00:27

0:00:27

0:00:31

0:00:31

0:00:16

0:00:16

0:00:16

0:00:16

0:00:34

0:00:34

0:00:56

0:00:56

0:00:35

0:00:35

0:00:27

0:00:27

0:00:19

0:00:19

0:00:16

0:00:16

0:00:11

0:00:11

0:00:25

0:00:25

0:00:16

0:00:16

0:00:33

0:00:33

0:00:24

0:00:24

0:00:18

0:00:18

0:00:27

0:00:27

0:00:25

0:00:25

0:00:30

0:00:30

0:00:23

0:00:23

0:00:22

0:00:22