filmov

tv

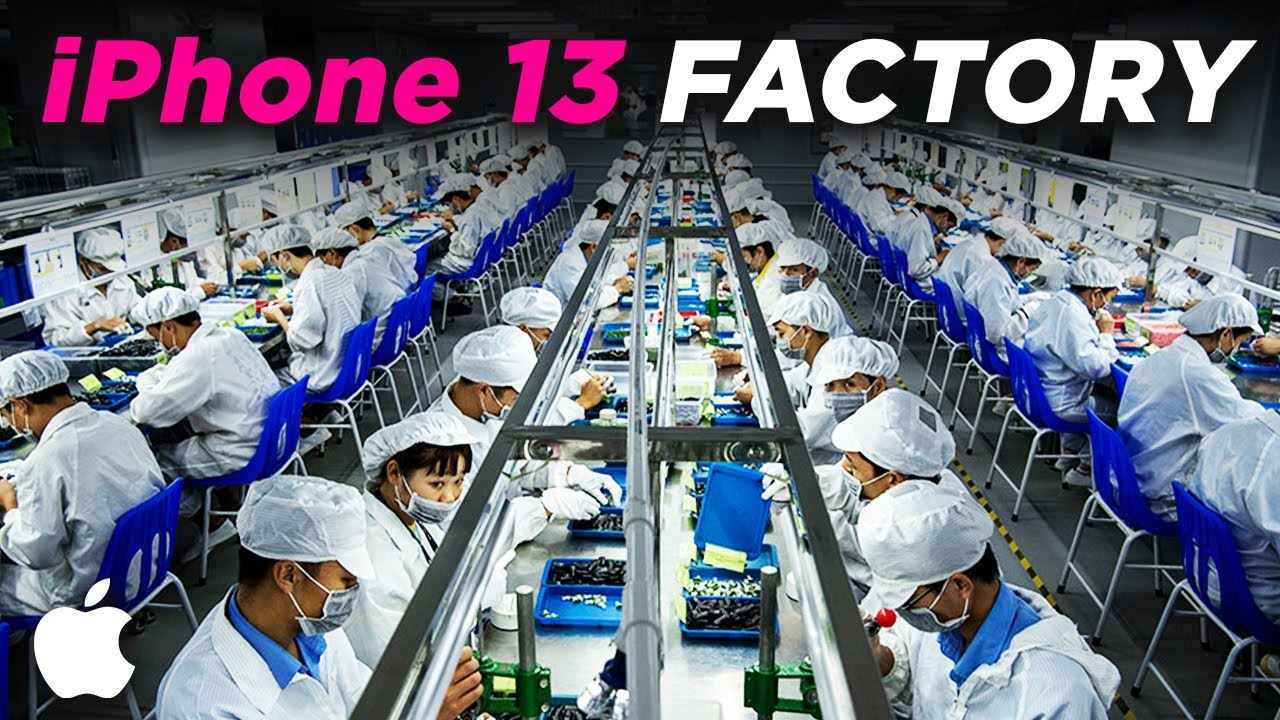

Inside Apple’s INSANE iPhone 13 Factory!

Показать описание

In this video, we will take a look inside the iPhone factory.

iPhone is one of the most well-known modern phones in the world. Since its inception, Apple has sold more than a billion units worth hundreds of billions of dollars. iPhone has helped to revolutionize mobile phone trends and many individuals’ ways of life. A big part of Apple's fame is from its ability to innovate a fantastic technology. Millions of customers worldwide are willing to pay top dollar for the quality, design, and features of the Apple iPhone. However, many users may not understand how manufacturers produce iPhones. Well, the truth is that your iPhone was not manufactured and designed in one country. Several countries and companies come together to create an iPhone.

If you have ever bought an iPhone or another Apple product, you would have seen the note on its packaging that its products are designed in California, but that doesn't mean they're manufactured there. So, where are iPhones manufactured? And what is it like to be inside the Apple iPhone factory?

When trying to understand how and where Apple manufactures its devices, it depends on two vital concepts which sound similar but quite different: assembling and manufacturing.

Manufacturing is the process of making the components that go into the iPhone. Although Apple designs and sells the iPhone, it doesn't manufacture its components. On the other hand, assembling is the process of taking all the individual components built by specialist manufacturers and combining them into a finished, working iPhone.

The most manufacturing process of an iPhone consists of buying the products from manufacturers and assembling them in good factories.

Apple iPhone sources its materials from all over the world. In an attempt to offer the very best technology at the lowest possible price, they are willing to scour the globe to get the best component manufacturer. At the same time, while searching for the best companies to work with, they need to partner and work with component manufacturers who can produce on a massive scale.

More than 200 companies worldwide manufacture and supply Apple iPhone manufacturers with their components to produce the phones. These component manufacturers create memory chips, glass screen interfaces, casings, cameras, and everything in between. The location of these component manufacturers varies widely. Components come from companies in South Korea, China, Taiwan, Germany, Japan, India, and many other countries, including the United States.

These suppliers send their manufactured components to massive Apple manufacturing factories worldwide for additional manufacturing and assembling. The assembling of the iPhone mostly takes place in East and Southeast Asia, where the labor force is cheap and abundant. So, the components go to Apple iPhone factory locations in China, the Czech Republic, Malaysia, Thailand, South Korea, Singapore, and the Philippines. Although iPhone manufacturing facilities are located in many countries worldwide, these manufacturing facilities are part of only two manufacturing companies, Foxconn and Pegatron. These Taiwanese firms manage iPhone production and ensure the completed phones are delivered on time and with the quality standards, Apple demands.

However, nothing is quite like the massive Foxconn plant located in Zhengzhou, China. The Foxconn factory, also called iPhone city, is a factory that spreads across 2.2 million square miles. One of the most significant advantages it has is the fantastic assembly line. The Foxconn factory employs approximately 350,000 people. Foxconn is Apple's longest-running partner in building Apple's iPhone. Foxconn currently assembles the majority of Apple's iPhones in its Shenzen, China, location.

iPhone 13 is awaited and the iPhone 13 will bring a lot of new features to upcoming iPhones, it may be iPhone 13 pro and iPhone 13 mini. What we know is that iPhone 13 will be released soon and we will show the release date and leaks. iPhone 13 will also have a better camera and you can expect the iPhone 13 review as well.

iPhone is one of the most well-known modern phones in the world. Since its inception, Apple has sold more than a billion units worth hundreds of billions of dollars. iPhone has helped to revolutionize mobile phone trends and many individuals’ ways of life. A big part of Apple's fame is from its ability to innovate a fantastic technology. Millions of customers worldwide are willing to pay top dollar for the quality, design, and features of the Apple iPhone. However, many users may not understand how manufacturers produce iPhones. Well, the truth is that your iPhone was not manufactured and designed in one country. Several countries and companies come together to create an iPhone.

If you have ever bought an iPhone or another Apple product, you would have seen the note on its packaging that its products are designed in California, but that doesn't mean they're manufactured there. So, where are iPhones manufactured? And what is it like to be inside the Apple iPhone factory?

When trying to understand how and where Apple manufactures its devices, it depends on two vital concepts which sound similar but quite different: assembling and manufacturing.

Manufacturing is the process of making the components that go into the iPhone. Although Apple designs and sells the iPhone, it doesn't manufacture its components. On the other hand, assembling is the process of taking all the individual components built by specialist manufacturers and combining them into a finished, working iPhone.

The most manufacturing process of an iPhone consists of buying the products from manufacturers and assembling them in good factories.

Apple iPhone sources its materials from all over the world. In an attempt to offer the very best technology at the lowest possible price, they are willing to scour the globe to get the best component manufacturer. At the same time, while searching for the best companies to work with, they need to partner and work with component manufacturers who can produce on a massive scale.

More than 200 companies worldwide manufacture and supply Apple iPhone manufacturers with their components to produce the phones. These component manufacturers create memory chips, glass screen interfaces, casings, cameras, and everything in between. The location of these component manufacturers varies widely. Components come from companies in South Korea, China, Taiwan, Germany, Japan, India, and many other countries, including the United States.

These suppliers send their manufactured components to massive Apple manufacturing factories worldwide for additional manufacturing and assembling. The assembling of the iPhone mostly takes place in East and Southeast Asia, where the labor force is cheap and abundant. So, the components go to Apple iPhone factory locations in China, the Czech Republic, Malaysia, Thailand, South Korea, Singapore, and the Philippines. Although iPhone manufacturing facilities are located in many countries worldwide, these manufacturing facilities are part of only two manufacturing companies, Foxconn and Pegatron. These Taiwanese firms manage iPhone production and ensure the completed phones are delivered on time and with the quality standards, Apple demands.

However, nothing is quite like the massive Foxconn plant located in Zhengzhou, China. The Foxconn factory, also called iPhone city, is a factory that spreads across 2.2 million square miles. One of the most significant advantages it has is the fantastic assembly line. The Foxconn factory employs approximately 350,000 people. Foxconn is Apple's longest-running partner in building Apple's iPhone. Foxconn currently assembles the majority of Apple's iPhones in its Shenzen, China, location.

iPhone 13 is awaited and the iPhone 13 will bring a lot of new features to upcoming iPhones, it may be iPhone 13 pro and iPhone 13 mini. What we know is that iPhone 13 will be released soon and we will show the release date and leaks. iPhone 13 will also have a better camera and you can expect the iPhone 13 review as well.

Комментарии

0:08:18

0:08:18

0:12:14

0:12:14

0:07:14

0:07:14

0:08:14

0:08:14

0:00:51

0:00:51

0:00:34

0:00:34

0:01:01

0:01:01

0:00:25

0:00:25

0:00:36

0:00:36

0:00:13

0:00:13

0:13:21

0:13:21

0:09:53

0:09:53

0:00:36

0:00:36

0:12:26

0:12:26

0:02:17

0:02:17

0:00:33

0:00:33

0:11:55

0:11:55

0:00:58

0:00:58

0:00:40

0:00:40

0:08:59

0:08:59

0:05:33

0:05:33

0:01:00

0:01:00

0:00:50

0:00:50

0:00:09

0:00:09